Completed

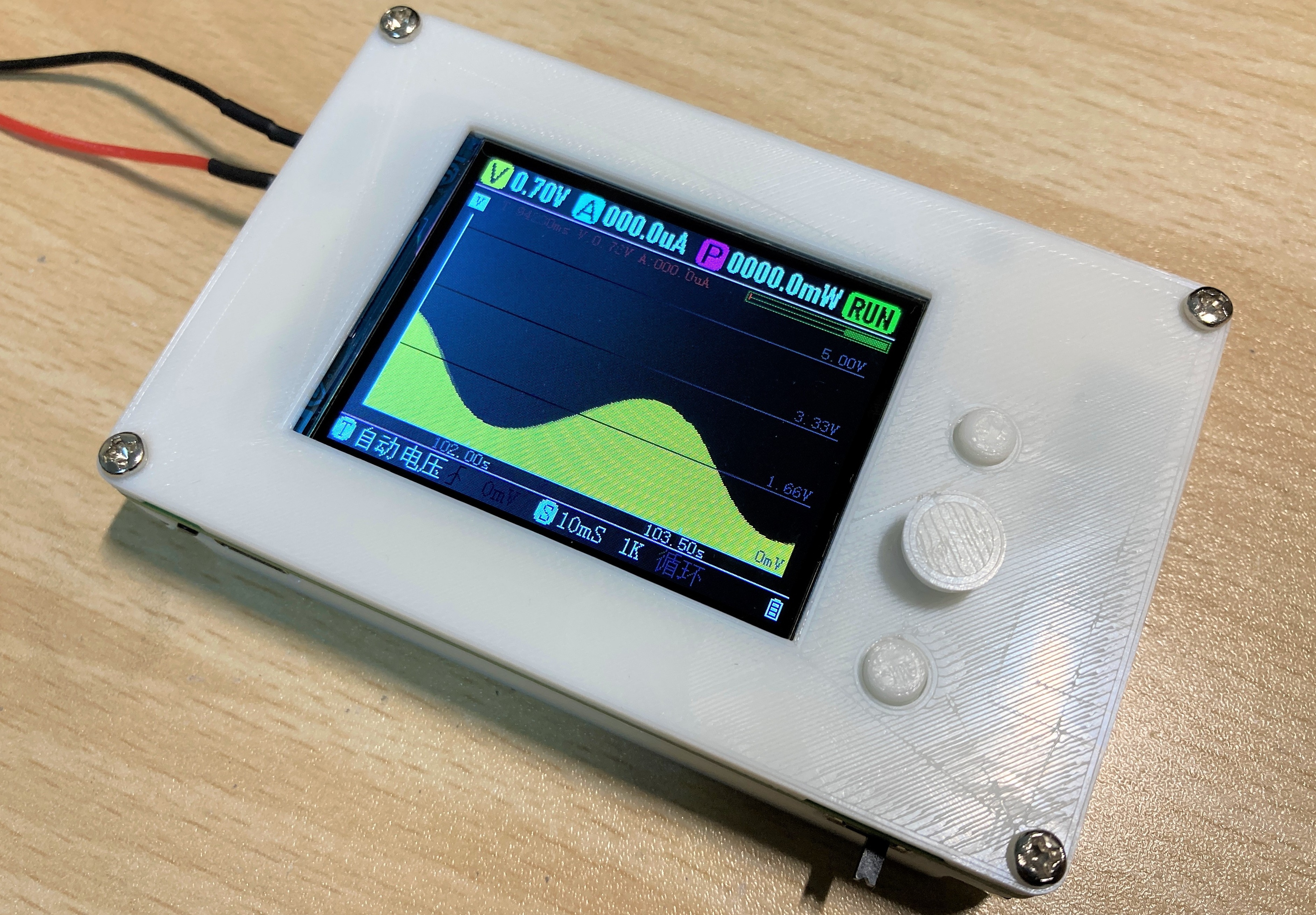

CompletedSmall Power Analyzer

PRO Small Power Analyzer

Small Power Analyzer

782

0

0

0

Mode:Full

License

:GPL 3.0

Creation time:2024-08-27 03:48:10Update time:2024-08-28 07:57:38

Description

Designed by micespring (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor.Add to Album

0

0

Share

Report

Followers0|Likes0

Related projects

Empty

Empty

Comment