Completed

CompletedMRDK1A - 32MR_PLC Industrial Programmable Logic Controller

PRO MRDK1A - 32MR_PLC Industrial Programmable Logic Controller

MRDK1A - 32MR_PLC Industrial Programmable Logic Controller

License

:CC BY-NC-SA 4.0

Description

32-Channel programmable logic controller based on STM32F1 series MCU design

MCU programming software: keil 5

Ladder diagram programming software: Gxworks2

Open source license: CC-BY-NC-SA-4.0 (This product is only for PLC working principle, programming learning, teaching use, and is prohibited for any form of commercial use)

Basic parameters: Power supply: 220V-0.3A

Output mode: relay

Input range: 5~ 24V

Output touchpoint capacity: AC250V-5A DC310V-3A

Number of output units: 32 (IN: 16P---OUT: 16P)

Series product naming:

The default is relay output. If you need transistor or thyristor output, you can directly replace the mechanical relay with a solid-state relay, or redesign the output unit.

The main control uses the STM32F1 series MCU, which can port programs to other platforms or add and delete units. The selected MCU: RAM memory should not be less than 48K, and Flash memory should not be less than 256K.

Host peripherals and communication unit.

The main power supply (when selecting the inductor of L1, attention should be paid to the DCR value below 20mΩ). If it is higher than that, it will cause the DC-DC to generate a large amount of heat in the working state (which may affect the long-term stability).

IO unit circuit

Output drive principle: MCUIO > > Optocoupler isolation > > 2803 drive > > Relay

Input driver: 5~ 24V signal > > Optocoupler isolation > > MCUIO

PCB-3D

Shell

Laser sintered nylon shell

If used under harsh conditions, it is recommended to add a shielding cover to the control circuit to enhance its anti-interference ability under harsh conditions.

Sheet metal shell plate thickness should be 0.1~ 0.2mm JLC sheet metal minimum can only be 0.5mm, if 0.5mm plate thickness should be welded with the main board installation.

The back shell is fixed with reeds and C45 guide rails.

Spring: 0.6 * 4 * 15.

RTC clock battery.

Gxworks2 configuration instructions.

In Gxworks2 PLC model selection FX2N create project.

Communication selection: RS232 communication, and select the corresponding serial port.

PLC Test Procedure 1: Three Motor Sequential Start and Stop.

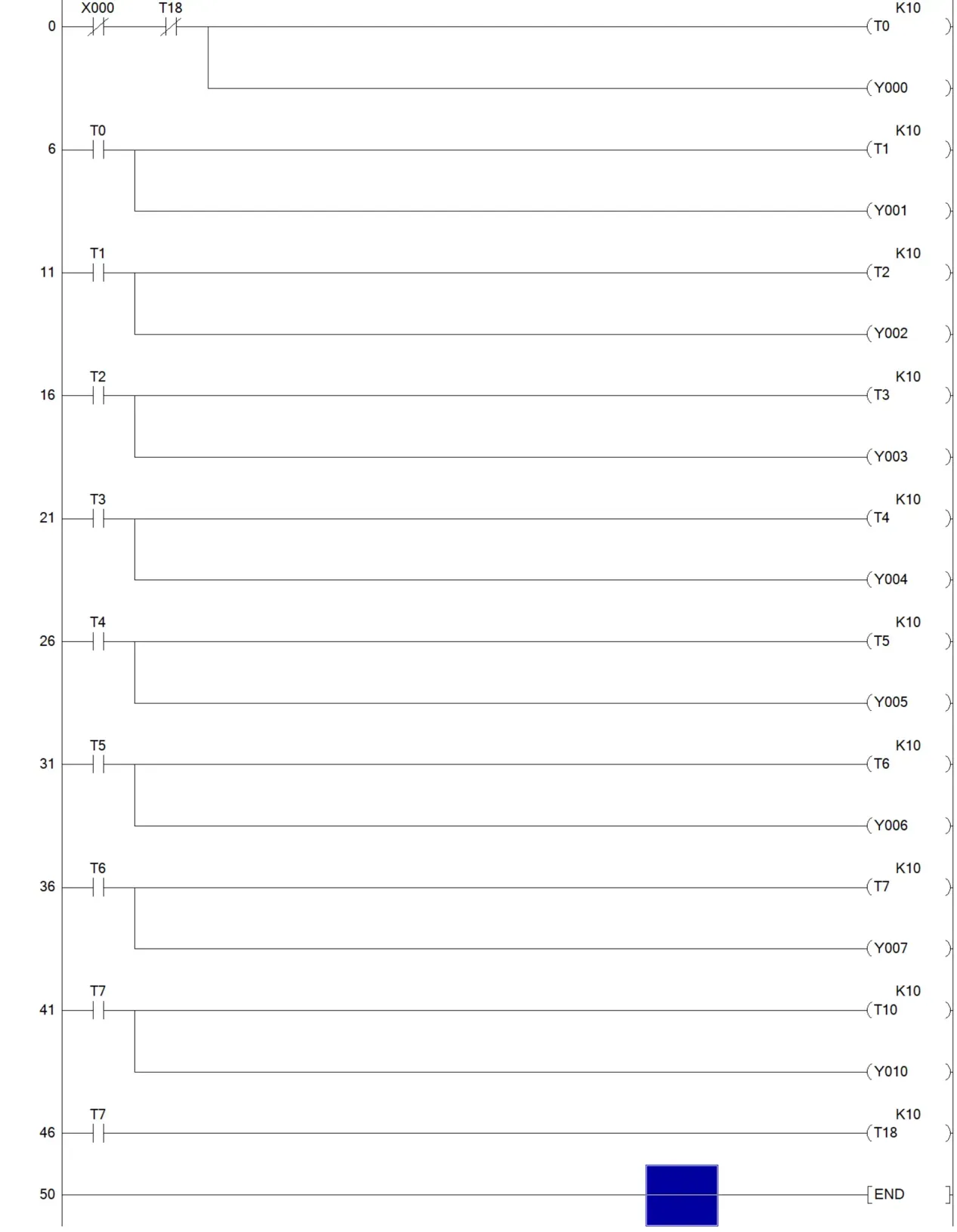

PLC test program 2: running light (delay 1s)

Test video: https://www.bilibili.com/video/BV144f3YcEp8/?vd_source=f2ecf6d07c56387a85d94b5338693a63

Program, shell, routine see engineering attachment

Designed by 模成Electron (from OSHWHub)

Link:https://oshwhub.com/dingcheng/mrdk1a-16mrplc-industrial-progra

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment