Completed

CompletedLittle North Pole の Ice Ice Cup (Summer)

PRO Little North Pole の Ice Ice Cup (Summer)

Little North Pole の Ice Ice Cup (Summer)

License

:CC BY-NC-SA 3.0

Description

In the hot summer, how to relieve the heat? An ice-cold drink is the ultimate answer! Now, the Little Arctic Ice Cup is here to bring you a refreshing experience like never before.

The Little Arctic Ice Cup uses semiconductor refrigeration sheet technology, which is portable and quickly cools, allowing you to enjoy cold drinks anytime, anywhere. Whether it's an iced Coke or an iced coffee, Little Arctic can do it all.

![]() Built-in temperature monitor to keep track of temperature changes in the cup. No more worrying about drinks getting warmer and enjoy every sip of ice.

Built-in temperature monitor to keep track of temperature changes in the cup. No more worrying about drinks getting warmer and enjoy every sip of ice.

![]() Intelligent speed adjustment function, adjust the fan speed according to needs, humanized noise reduction.

Intelligent speed adjustment function, adjust the fan speed according to needs, humanized noise reduction.

Cup detection function, identification status, energy saving. It's safer to use, and you can rest assured.

Cup detection function, identification status, energy saving. It's safer to use, and you can rest assured.

Through the Internet of Things, remote monitoring and control can be realized, and the temperature status in the cup can be grasped anytime and anywhere, and cold drinks can be prepared for you in advance.

Through the Internet of Things, remote monitoring and control can be realized, and the temperature status in the cup can be grasped anytime and anywhere, and cold drinks can be prepared for you in advance.

The design is sleek, portable and practical.

The design is sleek, portable and practical.

Open-source protocol

This project uses the CC-BY-NC-SA 3.0 open source license, which is Creative Commons License-Attribution-NonCommercial-ShareAlike.

PCB preview

3D shell preview

Project properties

This project is the first public and is my original project. The project has not won an award in another competition.

Feature description

- PD input: ≥65W

- DC input: 12V to 15V

- Operating current (sample): ≤3A

- Refrigeration power consumption (sample): <50W

- Heat dissipation current (sample): ≤200mA

- No-load minimum temperature (sample): -5°C

- Minimum temperature (half load) with load: +7°C

- Minimum temperature with load (full load): +12~+15°C

- ---------------------------------------------------------------------------------------------

- Note 1: The maximum temperature of the copper sheet at the heat dissipation outlet in refrigeration can reach 53°C, the temperature is very high, and it will not be burned!!

- Note 2: Refrigeration temperature; Affected by the environment, conductive medium, voltage, current, cold sheet power and other factors, the test samples are for reference only!!

- Tip 1: Metal cup temperature conduction material: Gold, 3E, silver, 3E, copper, and 3E. iron

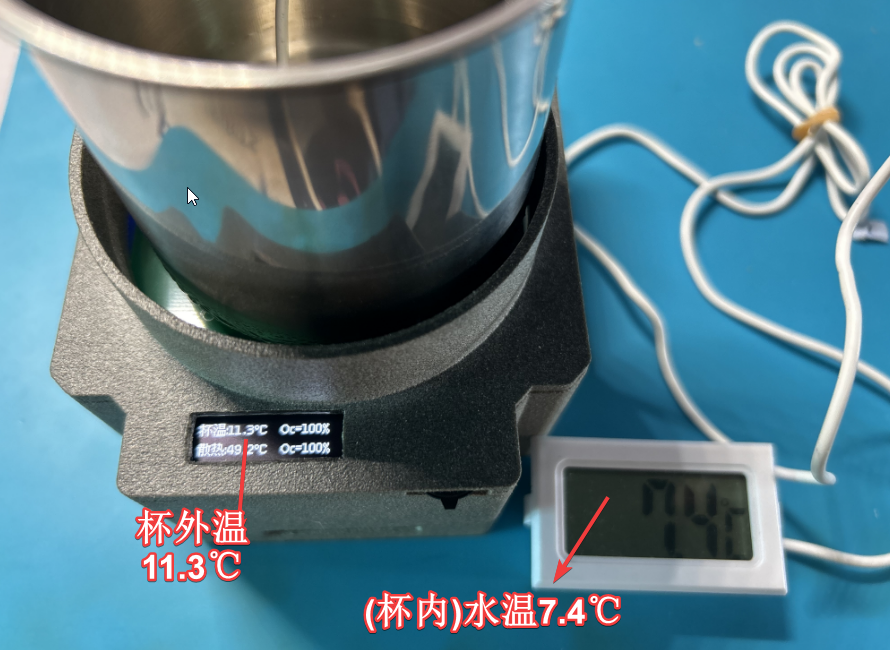

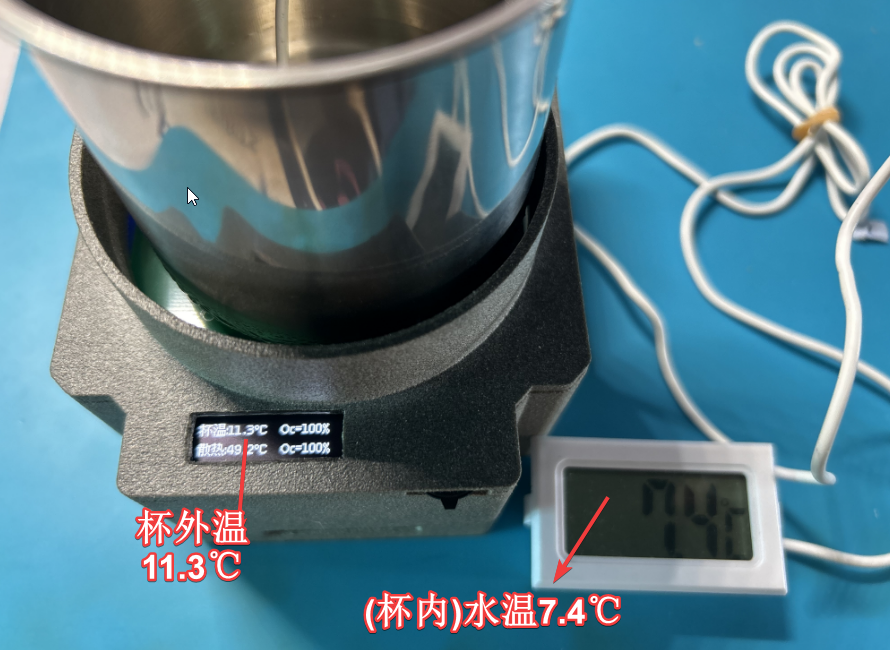

- Tip 2: Water Absorbent Characteristics, Measure Cup Temperature > Actual Water Temperature Error≈2°C For example: Cup temperature is 11.4°C, actual water temperature is 9.5 degrees Celsius. As shown in the figure below

- Tip 3: Due to the presence of condensation, 704 liquid silicone may be required to seal, some sensors, the picture and text will be updated in the future!!

Feature description

- Support cooling power adjustment ✓

- Support PWM intelligent cooling control ✓

- Supports cup placement detection ✓

- Support PD, DC dual power input ✓

- Temperature detection: environment, chip, refrigeration, heat dissipation ✓

- Temperature Reminder (WIP)

- Temperature & Status Display ✓

- Remote monitoring and control function (under development)

- Menu function control: buzzer, alarm, power (support power-off storage) ✓

- Key Logic Control

Changelog 2024.7.4

1. Increase the cup detection during use, the cup is picked up and enters the timing shutdown stage, during which the speed reduction heat dissipation lasts for 25S, and the cup will continue to be refrigerated before the end of the timer, otherwise it will switch to a stop state.

2. During the heat dissipation process, all functions of the button are disabled, and it is enabled after stopping.

Changelog 2024.7.31

- There are a lot of private messages asking questions, and some bigwigs have made it without assembly drawings and parts provided.

- Since C3 has 2M 4M two versions (negligence is not remarked), resulting in some people buying 2M can be used, 4M can not be started after brushing, and the update provides 2 versions of the program (urgent)

{Software}

1. Fixed the key timeout, and fixed the impact of jumper during debugging.

2. Adjust the starting power to prevent the power from reaching the power supply, start the instant overload protection, and restart repeatedly.

{Hardware}

1. Update the model of the lower BOM input fuse (copy the component to change the parameters)

Physical display

Interactive

Product assembly and accessories

The overall function of the hardware and software is normal, it has been verified to use, and the relevant details will be updated in the future. . .

Related accessories are uploaded in the follow-up in the collation of graphic assembly data. . .

Demo Video (To be continued...) Reading this is all true love, just click on it.

Designed by Origin_ (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment