Completed

CompletedKyushu -- Klipper nine-axis 3d printer motherboard

PRO Kyushu -- Klipper nine-axis 3d printer motherboard

Kyushu -- Klipper nine-axis 3d printer motherboard

License

:GPL 3.0

Description

Project Description

The original intention of the 3D printer nine-axis motherboard that can use KLIPPER or malin firmware is to further reduce the cost of 3D printer production and catch up with the Spark Project. Moreover, the requirements for the circuit design of the printer motherboard are still relatively challenging, and the code development is not so complex. If you want to use klipper firmware, you need to use it with the host computer.

Open Source Agreement

GPL 3.0.

Open source and free use of code and open source and free use of reference, modification, and derivative codes, but modified and derivative codes are not allowed to be released and sold as closed source commercial software.

Project Related Functions and Features

- ESD protection for each port and back electromotive force protection for stepper motors;

- ARM-M4 180MHZ main control;

- Removable fuse;

- Three heating heads and one heating bed adopt high-power MOSFET;

- Six-way controllable fans (pipe/blowing material), three-way normally open fans (mainboard, driver cooling);

- Fan voltage selection: 5V, 12V, 24V;

- Five-channel NTC100K temperature measurement;

- Support PT100 high temperature sensor;

- X/Y/Z limit, and two additional limits are reserved;

- Nine-axis replaceable stepper motor drive;

- The stepper motor working mode supports STEP/DIR standard mode, TMC UART mode, and SPI mode;

- X ,Y support high voltage drive (within 60V);

- Onboard 32Kb EEPROM;

- Reserve UART1 for serial port screen or other communication;

- Reserved LCD screen interface;

- Support external USB flash drive;

- 3DTOUCH automatic leveling sensor interface;

- RST button/BOOT0 interface/SWD debugging download interface;

- TF card holder;

- Support Klipper or Marlin firmware;

- type-c communication interface;

- CAN communication interface;

- PROBE proximity switch interface;

- RGB interface (supports voltage selection);

- Supports breakpoint continuation;

- Support automatic shutdown;

- Support stall detection (need to use a driver that supports stall detection, such as TMC2209, etc.);

- Adopts Type-C interface and supports online printing;

- Adopts a dedicated power chip and supports 24V power input;

- Using high-performance MOSFET tubes, the heat dissipation effect is better.

Project Properties

Publicly available for the first time, has not won any prize in other competitions, etc.

Project Progress

On January 31, 2023, the PCB main body will be completed and awaiting proofing verification.

On May 21, 2023, all Chinese annotations for the printer were completed, verifying the feasibility.

Design Principles

The 3D printer motherboard based on STM32F446ZET6 supports up to 9-way stepper motors and can support full UART mode. The klipper firmware can be compiled online, reducing the tedious process of modifying the firmware code.

Software Description

The attached printer is the main configuration file of klipper, which has been annotated in Chinese.

Motherboard Parameters

1) Appearance size: 185*100mm.

2) Installation size: 175*90mm.

3) Microprocessor: ARM 32-bit Cortex™-M4 CPU.

4) Input voltage: DC24V.

5) Motor driver: pluggable driver.

6) Electric connection: MOTOR0, MOTOR1, MOTOR2_1, MOTOR2_2, MOTOR3,MOTOR4, MOTOR5, MOTOR6, MOTOR7, MOTOR8.

7) Temperature sensor interface: T0, T1, T2, T3

8) Display: LCD12864, LCD2004, etc.

9) PC communication interface: Type-C, easy to plug and unplug.

10) Expanded interface function support: material break detection, resume printing after power outage, shutdown after printing, BL_Touch,etc.

11) Supported file format: G-code.

12) Recommended software: Cura, Simplify3D, pronterface, Repetier-host, Makerwar.

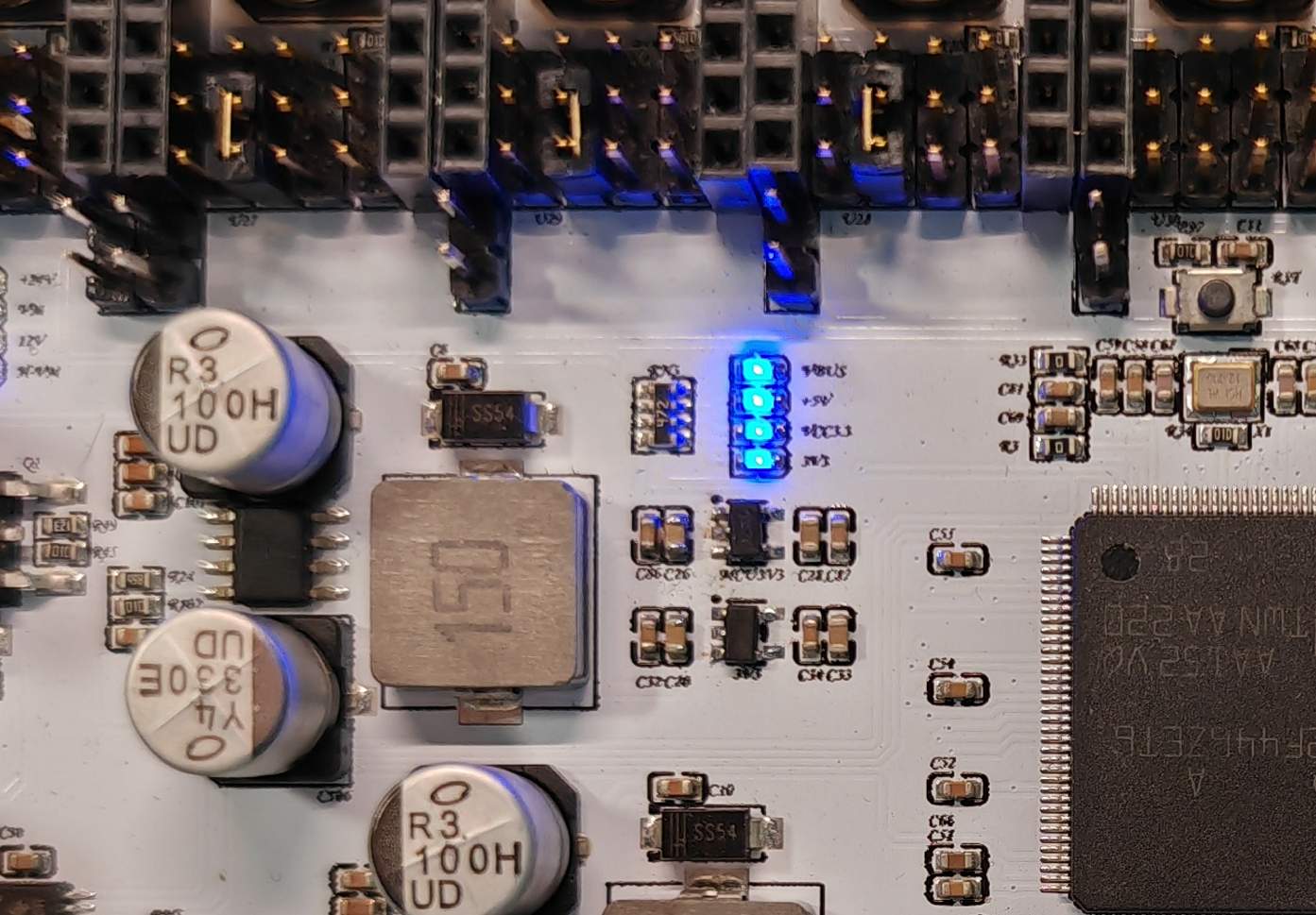

Physical Display

Precautions for Use

Motherboard Wiring Method

1. Main Power Wiring

2. Stepper motor jumper

1.STEP/DIR mode

When using the driver module working in STEP/DIR mode, it is necessary to use the jumper cap to select the subdivision according to the subdivision table corresponding to the driving module used.

Note: The needle rows from left to right are SLP, MS3, MS2, MS1. The low level is connected to the bottom two rows of needles, and the high level is connected to the top two rows of needles. If the A4988 or DRV8825 driver is used, the RST and SLP must be shorted with the jumper cap to work properly.

2. UART Mode

When using a driver working in UART mode, the pins need to be shorted with a jumper cap as shown in the figure above.

3. SPI Mode

When using a drive operating in SPI mode, the lower and middle positions of the row pins need to be shorted with jumper caps, respectively.

3. Fan jumper

When using, short-circuit the pin headers on the left and right in the picture above according to the fan voltage. The terminals should be negative at the top and positive at the bottom. Remember not to reverse the connection, as it will burn the fan.

4. Use Stall Detection

Stall detection requires the use of a drive module with stall detection function, such as TCM2209, TMC2226.

When in use, short-circuit the two pin headers located under each driver.

5. Firmware Burning

Use ST-LINK to connect the motherboard SWDIO\SWCLK and connect it to the computer. If the hardware is correct, download STM32CubeProgrammer on the computer, change the mode to ST-LINK, and import the attached file for flashing.

6. Precautions

1) Before powering on, ensure that all wires and jumper caps are correctly connected and complete.

2) The Type-c interface does not support powering external devices.

3) It is recommended that the power of the hot bed is less than 300W. When using the hot bed with high power, please use the external hot bed module.

4) The actual pin sequence is subject to PCB.

Communication group: 780283357

Designed by DongDuZhiLang (from OSHWHub)

Link:https://oshwhub.com/dongduzhilang/KLIPPER-ba-zhou-3dda-yin-ji-zhu-

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment