Completed

CompletedA distributed wireless measurement and control platform

PRO A distributed wireless measurement and control platform

A distributed wireless measurement and control platform

License

:Public Domain

Description

As mentioned in the introduction, this is a wireless measurement and control platform used in engineering experiments.

Wireless Measurement v2.1 was released on 2023/12/01, the address is https://oshwhub.com/starsky2019/micro_measure. On the basis of this project, some improvements have been made to improve the integration.

Demo video address:https://www.bilibili.com/video/BV1ru4y1G7Xt/

1. What is wireless measurement and control?

Experiments are inseparable from data, and the values of various physical quantities are collected by sensors. Simply put, this process is measurement. During the experiment, we need to constantly adjust devices such as valves, lasers, and motors. This process is control. The so-called measurement and control is the integrated process of measurement and control. Wireless measurement and control is a more convenient and flexible method developed on the basis of traditional measurement and control technology. It uses radio frequency to transmit signals, gets rid of a large number of wiring in traditional measurement and control systems, is easy to install, and has good scalability. But the shortcomings are also obvious: the signal coverage is limited and susceptible to interference, which may pose data security risks.

2. What did this project do?

This project started with a customized thermocouple signal acquisition board for the hypersonics laboratory. Later, after redesigning the PCB, the hardware applicability was greatly improved. In the end, the author improved the software support and open sourced the project to oshwhub, aiming to provide stable and efficient wireless measurement and control solutions for friends.

The wireless measurement and control described in the project consists of two parts: wireless measurement system and wireless control system. The two work independently without interfering with each other.

(1) Wireless measurement

●Collect -6mV~54mV voltage signal, or 4-20mA current signal.

●Use AD7327 chip as analog-to-digital converter to achieve 12-bit accuracy.

●Each measurement PCB supports eight-channel asynchronous acquisition.

●Support real-time display of data on the web page.

●Logs and data are backed up on the server side.

●The microcontroller at the experimental site is connected to an SD card, and data will not be lost when the network is disconnected.

(2) Wireless control

● Remotely control the on and off of a certain channel’s DC voltage, which can be used to drive valves, etc.

● Maximum continuous load current up to 5A.

● Each PCB supports eight channels.

● Supports timing control and manual control, timing accuracy reaches 1ms, and synchronization delay is less than 0.3ms.

● Equipped with emergency stop device.

● Logs are backed up on the server side.

In experimental environments with a large number of measurement and control channels and inconvenient wiring, wireless measurement and control systems have high application value.

3. System design ideas

The entire system includes two servers (using WebSocket and HTTP protocols respectively) and several nodes. Its structure is as follows:

Among them, the nodes are distributed at the experimental site and are divided into measurement and control nodes, which are responsible for measuring sensor signals and issuing control voltages respectively. The server is responsible for connecting users and nodes so that users can observe node data and change the status of the control channel.

The WebSocket server supports establishing connections with up to 98 nodes, and their addresses are 001-098. There is an auxiliary window program (hereinafter referred to as the "auxiliary program") hanging at the 099 address in the WebSocket network, which is used to check the server status, manage the server's restart and shutdown actions, etc. Because the 099 address is also connected to the server through WLAN, it and the server do not need to be running on the same computer.

Note: The node addresses are prefixed with 's' and 'm' respectively to distinguish the control server and the measurement server. That is, in the control server, the node address is s001-s099; in the measurement server, the node address is m001-m099.

The HTTP server broadcasts two web pages, responsible for wireless measurement and wireless control: the measurement web page supports real-time viewing of node data; the control web page supports manual changes to the status of a channel. The HTTP server is built on Apache2.4. In the provided software package, Apache2.4 and PHP8 will be installed when installing the server, and the root directory of the web page will be automatically modified.

The following three sections will specifically describe the principles and functions of the server and measurement and control nodes. Section 7 will introduce how to use the system for wireless measurement and control.

4. Server and auxiliary programs

The release version installation package of the server and auxiliary programs has been uploaded to Lanzoue Cloud, and the download address is https://wwer.lanzoue.com/iNjXz1hd9weh .

4.1 Server installation

(1) Download the compressed package and unzip it, open the Server folder.

(2) Double-click setup.exe and select the installation path.

※The installation path cannot contain Chinese characters.

※The installation path cannot have spaces or special symbols.

※Try not to choose the installation path on the C drive, otherwise file access may be denied.

(3) Wait for the server installation to complete.

(4) Return to the desktop and double-click DoubleClickMe.lnk

(5) Wait for the program to end and press any key to exit.

At this time, DoubleClickMe.lnk is automatically deleted on the desktop, leaving two shortcuts: ApacheMonitor and WS_Server. The former is the entrance to Apache2.4, and the latter is the startup shortcut of the WebSocket server.

Note: If you want to recompile the server, the cpp source file is provided in the installation path. Please go to github to install the WebSocketpp and boost libraries for C++ yourself.

4.2 Server startup

(1) Go to the desktop, double-click WS_Server, and the following prompts will pop up:

① Do you want to obtain the IP information of this machine?

If you select Y, ipconfig will be executed in the program and the server's IP will be displayed; if you select N, this step will be skipped.

The author recommends selecting Y to view the IP and remember it. This IP is needed in the process of auxiliary program connection and node network configuration.

② Measure the number of links of nodes:

How many measurement nodes are expected to join the network, the helper program is also counted as a node. Enter an integer, such as: 2

③ Number of links to control nodes:

Same as above

④ The sampling frequency (sps) of the measurement node is:

Enter an integer indicating how many times the measurement node samples in one second.

This value only changes the time coordinate of data refresh in the web page, which must be consistent with the sampling frequency of the microcontroller in the measurement node. The sampling frequency of the microcontroller defaults to 1000sps, and its modification method will be introduced below.

⑤ Do you want to start the server?

Enter Y to start.

After (1), the computer has established two WebSocket servers in the WLAN. The address of the wireless control server is ws://localhost:9002, and the address of the wireless measurement server is ws://localhost:8002. If the server fails to start, please check whether the port is occupied.

(2) Go to the desktop, double-click ApacheMonitor, and start Apache2.4

At this point, the computer has begun broadcasting web pages to the LAN. Access localhost/user_measure through a browser to view the measurement web page, and access localhost/user_control to view the control web page. For users other than the server, please replace localhost with the server's IP, and then access the web page.

4.3 Server function description

(1) Measure web pages

The interface is as shown below:

In the interface, the gray-green background square at the top displays the names of all online channels, and the drawing area is at the bottom. Click to select a channel, its background will change from gray to green, and the corresponding chart will be displayed below. Click again to deselect the channel and the corresponding chart and historical data will disappear. The banner at the bottom can fade out of the interface after clicking. The number on the upper right indicates the number of charts displayed in each row, which can be adjusted by clicking "+" and "-".

Note: When drawing many charts at the same time, it may cause high CPU usage.

Note: The microcontroller can distinguish different physical quantities by modifying the data suffix. The web page will automatically assign units after parsing these physical quantities. The way to distinguish different physical quantities will be introduced in Section 5.

(2) Control web pages

To prevent command conflicts, the control webpage only allows one user to operate online. Therefore authentication is required.

When you open the control page for the first time, the browser will prompt that the identity information has expired. Click "OK" to automatically jump to the login page. Enter your username and password. After successful login, you will be redirected to the control page and allowed to operate the status of each node channel through the web page.

If a user is already operating the control page, all subsequent login processes will be blocked. It takes about 3-6 seconds for the server to update the online status. After the previous user closes the web page, please wait for a while before logging in again.

On the login page, you can also choose "Register Account" or "Change Password". Among them, the initial verification code of "Register Account" is "ABCDEFG". Website administrators can modify it in "Installation Directory\Apache24\htdocs\user_control\config.txt". config.txt saves a json format string, and the item corresponding to the verification code is vfCode.

The main interface of the control web page is shown in the figure below. Click "+" and enter the channel name to create a new control channel. Click "ON/OFF" to change the on/off status of the channel. Click the "X" to close the current channel. The bottom banner can also be closed with a single click.

Note: The control web page supports manually changing the status of a channel, but it is still connected to the server through WebSocket. Please make sure that you do not operate the helper program and the web page at the same time, otherwise they may conflict.

Note: Sometimes due to abnormal shutdown of the server, the control login page will mistakenly display the user who is operating. Please confirm that all users are offline, then go to "Installation Directory\Apache24\htdocs\user_control\config.txt" and modify the corresponding value of "numofcon" to 0. Refresh the page after completion.

4.4 Installation of auxiliary programs

(1) Download the compressed package and unzip it, open the Client folder

(2) Double-click setup.exe, select the installation path, and start the installation

※The installation path cannot contain Chinese characters

※The installation path cannot have spaces or special symbols

※Try not to choose the installation path on the C drive, otherwise file access may be denied.

(3) Wait for the auxiliary program to be installed

After all is completed, a shortcut of MS_User will appear on the desktop, which is the entrance to the auxiliary program.

4.5 Function description of auxiliary program

Double-click to open MS_User, and you can see a total of 6 tabs, namely "Welcome", "Control Node Management", "Measurement Node Management", "Time Series Editing", "Time Series View" and "Time Series Start".

After the program is opened, it is offline by default and all functions are disabled. Please enter the server address in the "Welcome" interface and click "OK" to connect to the server. If you do this, a new command line window will be launched with WebSocket debugging information logged.

Open the "Control Node Management" tab, and the interface is as shown below. Among them, the far right side is the messages coming and going from the server, the upper left part has many buttons, and the lower left part is a scroll area.

When a control node is connected to the network, click "Update" to view the number of online links;

Click "Check Ping" to obtain the delay between each node and the server. The delay in milliseconds will be displayed in the scroll area;

Click "Start Injection" to distribute the timing file saved on the server (explained below) to the corresponding nodes, and check whether these nodes receive it successfully;

Click "Execution Preparation" will make each control node enter the "waiting for trigger state", which is a necessary condition for starting the control sequence;

Click "Server Restart" or "Server Shutdown" to restart or shut down the server corresponding to ws://localhost:9002.

Open the "Measurement Node Management" tab, the interface is as shown below. In this tab, the function of "Execution Preparation" is different: after the node is connected to the network, it is in standby state by default. At this time, clicking "Execute Preparation" will cause all nodes to start collecting data and continuously upload it to the server. If you click "Execute Prepare" again, the node will stop collecting and uploading, and return to standby status. Other functions are similar to the "Control Node Management" tab and will not be described here.

Open the "Timing Edit" tab, and the interface is as shown below.

Sequence control is a common control method that is used to automatically perform a series of operations in a predetermined time sequence. In this tab, we can select specific channels and specify their turn-on and turn-off times, and then make it into a timing file. Click "Browse" to select the path to save the timing file. Click "Add Node" to create a new node below the current node; click "Delete Node" to delete the current node; click "Clear" to clear all entered opening and closing times. Click "+" to add a control channel to the current node; click "x" to delete the last control channel of the current node. "On time" and "Off time" are measured in milliseconds. Enter several integers and separate the two numbers with a semicolon ";". After the timing editing is completed, click "Save" to generate a "server_seq.SEQ" file in the target folder.

Open the "Time Series View" tab, and the interface is as shown below. Open the saved timing file (*.SEQ), and the timing graph will be automatically displayed below. After checking, click "Send to Server" to transfer the file to the local server.

Open the "Sequence Start" tab, and the interface is as shown below. Enter the correct startup key, click "Start", and the program will enter a 5-second countdown. Then a start command is sent to the synchronizer, and then the synchronizer generates a trigger signal, causing each control node connected to it to start executing the sequence at the same time.

The function of the synchronizer and its wiring to each control node are described below.

Note: The following conditions must be met for the sequence to be successfully started:

① The synchronizer and each control node maintain wireless connections with the server.

② The key in the auxiliary program is consistent with the key entered in the synchronizer.

③ The trigger end of each control node is connected to the synchronizer and is in the "waiting for trigger state".

5. Design and function of measurement nodes

5.1 PCB board

The measurement node mainly contains three PCB boards: the power board, board A for measuring K-type thermocouple signals, and board B for measuring 4-20mA current signals.

(1) Power strip

The function of the power board is to provide a stable voltage of 5V for the two measurement boards, and to provide an interface for battery status and charging status indication. For the measurement node, the PCB name used for the power board is "UPS2". As shown below:

The power board uses two 3.7V lithium batteries connected in series, and obtains 5V after being regulated by AMS1117-5.0.

In the picture, BAT1 and BAT2 are two PH2.0 sockets, used to connect the battery ( ! Before connecting, please confirm whether the positive and negative poles of the battery are consistent with the silk screen! ). The two circular pads with through holes pointed to by the silk screen "SW" are the switch connection positions. The battery has output only when the two are short-circuited.

There are two AMS1117 soldering positions reserved in the PCB, and they are connected in parallel. If the load's current demand is less than 1A, you can just solder any AMS1117.

There is a lithium battery installation location reserved in the lower right corner of the PCB. The author uses a 603450 battery (Xubao). Two pieces are stacked and fixed with glue. The battery is shown below. Of course, if space permits, you can also replace the battery with a larger capacity and volume. However, the 3D shell provided in this project may not fit in, please redesign it.

There are six XH2.54 sockets on the far left side of the PCB, which are divided into three groups: "VIN", "VBAT" and "5V". Each group is short-circuited to each other and provides two positive and negative welding positions. The positive and negative electrodes are consistent with the silk screen.

The power board uses PL7501C to charge two lithium batteries and PL7022B to protect the two lithium batteries. When charging, please connect 5V to one of the XH2.54 sockets in "VIN". The default maximum charging current is 1A, please make sure the output current of the power adapter is sufficient.

This project also provides a small circuit board that converts the Type-C interface to 5V. The name of the PCB is "TypeC-5V". After welding the XH2.54 terminal wire to it, it can be directly plugged into the socket of the power PCB.

The "VBAT" socket is connected to the positive and negative poles of one of the batteries and outputs the current voltage of the battery for power monitoring of the measurement board.

"5V" outputs a stable 5V voltage to power both measurement boards. When charging, this voltage is output directly from VIN; when the battery is being discharged, this voltage is output by the AMS1117. The switching process will not affect the measurement board operation.

Note: There is another solution for the power supply: boosting the 3.7V of a single-cell lithium battery to obtain 5V, and the corresponding PCB name is "UPS". There is an empty slot on the left side of the PCB, and a large amount of tin needs to be piled on the pads on the edge to connect to the power module (a treasure) (as shown in the picture below). The recommended PCB proofing thickness is 1.2mm.

Note: The above boost scheme is not recommended for use in measurement boards. This solution has a large ripple and will bring considerable noise to the measured data.

Note: The above boost scheme is not recommended for use in measurement boards. This solution has a large ripple and will bring considerable noise to the measured data.

Note: Try not to measure while charging. Some power adapters have poor output voltage quality, which can also interfere with measurement results.

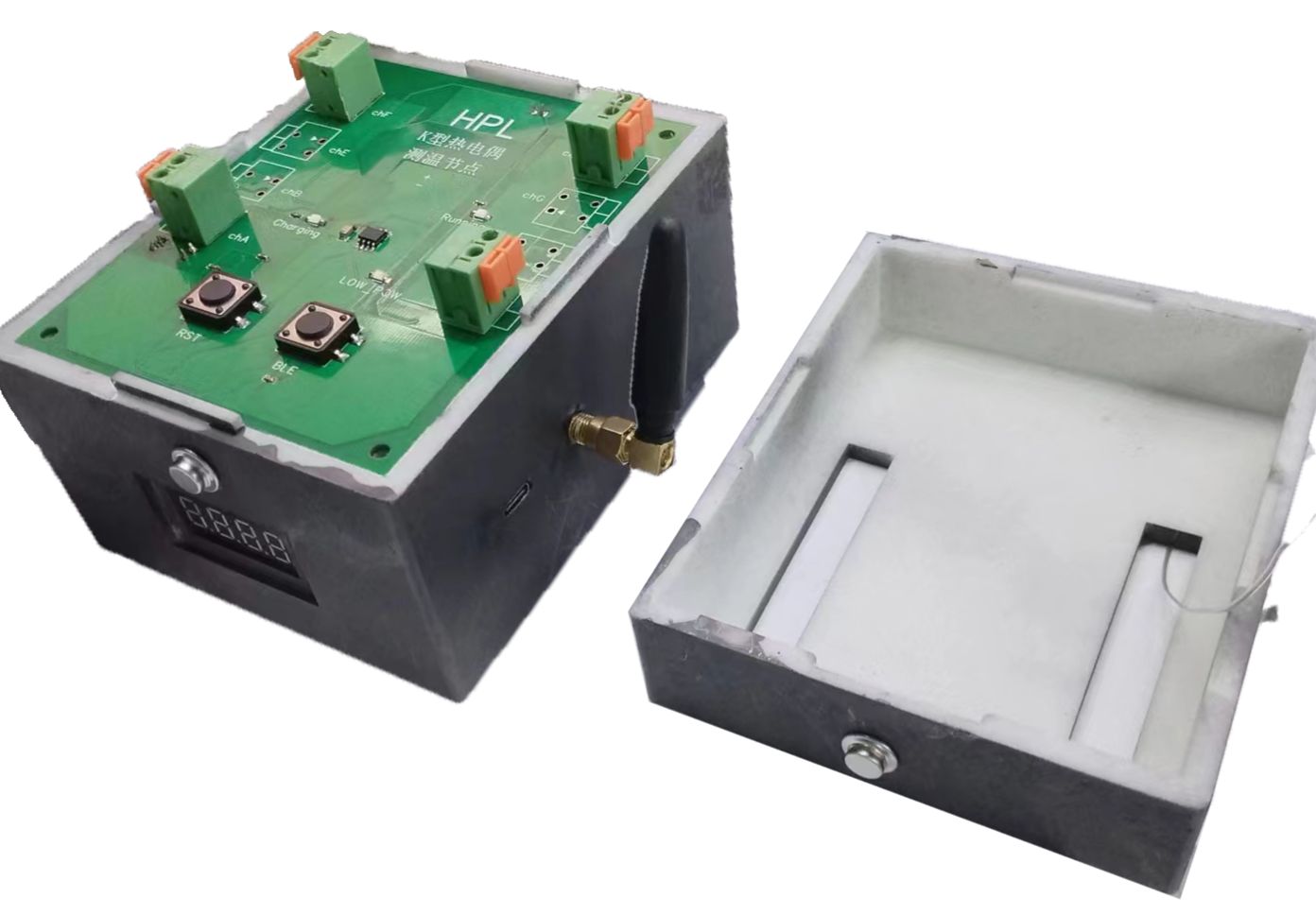

(2) Measuring plate for K-type thermocouple

The measuring plate of type K thermocouple is um_op. There are eight terminal blocks installed on the back of the PCB, which are directly connected to the K-type thermocouple. It uses OP07 to form a differential amplifier, amplifies the signal of the thermocouple, and inputs the amplified signal into the analog-to-digital converter AD7327. AD7327 is connected to the ESP32 microcontroller and is set as a slave to transmit data through SPI. The microcontroller is also equipped with MAX6675 and SD card, which are responsible for the cold junction compensation and data backup of the thermocouple respectively.

There is an SGM3204 mounted on the PCB to generate negative voltage. This allows the measurement plate to collect normally even if the hot end of the thermocouple is cooler than the cold end.

The top and bottom sides of the PCB are as shown below.

There are three XH2.54 sockets installed on the top surface, namely "5V", "VBAT" and "VIN", which correspond to the three sockets in the power strip. "5V" is the power supply socket; "VBAT" is the socket for battery power monitoring. After connecting, the indicator light will light up when the battery power is low. It can also work normally if not connected; "VIN" is the socket for charging status indication. After connecting The indicator light comes on while charging, and it also works normally without being connected. The socket indicated by the silk-screen "LED" on the lower left side of the top surface is an XH2.54-1x5P socket. It is connected to a four-digit digital tube to display the node number. As shown below (a treasure)

There are three XH2.54 sockets installed on the top surface, namely "5V", "VBAT" and "VIN", which correspond to the three sockets in the power strip. "5V" is the power supply socket; "VBAT" is the socket for battery power monitoring. After connecting, the indicator light will light up when the battery power is low. It can also work normally if not connected; "VIN" is the socket for charging status indication. After connecting The indicator light comes on while charging, and it also works normally without being connected. The socket indicated by the silk-screen "LED" on the lower left side of the top surface is an XH2.54-1x5P socket. It is connected to a four-digit digital tube to display the node number. As shown below (a treasure)

There are three LEDs on the bottom. The silk screen "Running" indicates that the measurement board is powered on, "charging" indicates that it is charging, and "LOW_POW" indicates that the battery power is low. There are two buttons under the bottom: the silk screen "RST" means restarting the microcontroller, and "BLE" means turning on Bluetooth (the function of Bluetooth will be explained below).

(3) Measurement board for 4-20mA current signal

The measurement board for 4-20mA current signal is um_420. It uses a precise sampling resistor of 150Ω to directly collect 4-20mA current, which will cause a maximum voltage drop of 3V. In my test environment, the current loop allows a maximum voltage drop of 12V. If the sampling resistor is too large, you can reduce the sampling resistor and add a first-level operational amplifier. You should ensure that the output voltage of the operational amplifier corresponding to 20mA is 3V.

The PCB of um_420 is basically the same as that of um_op. The top and bottom surfaces are as shown below:

The PCB of um_420 has no negative power supply and has two more terminals. This is because 4-20mA signals generally require additional power (mostly 24V), and using lithium batteries for power will cause high energy consumption. The two terminals shown on the silk screen "External Power Supply" are short-circuited. One of them is connected to the power supply, and the other can be connected to other measurement boards to achieve cascading.

The PCB of um_420 has no negative power supply and has two more terminals. This is because 4-20mA signals generally require additional power (mostly 24V), and using lithium batteries for power will cause high energy consumption. The two terminals shown on the silk screen "External Power Supply" are short-circuited. One of them is connected to the power supply, and the other can be connected to other measurement boards to achieve cascading.

5.2 Microcontroller

The program is compiled using ArduinoIDE. Since the program occupies a large amount of memory, the measurement board microcontroller uses the ESP32-WroverB module (some treasure), which is directly inserted into the outer rows of two rows of 2*19P parallel patch headers.

Note: The author recommends turning on PSRAM and changing the partition of the microcontroller to "HugeAPP".

The relevant programs for the microcontroller are found in the attachment. Among them, um is the measurement program for mounting the SD card. The program will not run normally when the SD card is not inserted. If the SD card is damaged or there is no need to mount the SD card, please burn um_noSD: except for the SD card, the functions are the same as um. K-type thermocouple measurement board and 4-20mA measurement board both use the above-mentioned microcontroller program.

The program of the microcontroller needs to import the external Websocket library. The library file can be found in the attachment "arduinoWebsockets-master".

Here are some instructions on the program:

(1) Bluetooth mode description

Each node has its own independent number and measurement mode, and each server also has a specific wireless LAN and IP address. This information often changes. If each change requires re-programming, this will be a tedious task and the applicability of the system will be greatly reduced.

Therefore, the microcontroller uses Bluetooth + EEPROM to store these key information. If they need to be modified, the user can use a Bluetooth device to access the microcontroller directly without going through the serial port. The advantage of this is that the information is easy to edit and will not be lost after power failure, and there is no need to repeatedly configure it; the disadvantage is that Bluetooth needs to be configured separately, and the program size increases significantly.

① How to enter Bluetooth mode?

If the microcontroller can connect to WLAN, you can click the "BLE" button to turn on Bluetooth when it is working normally;

If the microcontroller cannot connect to WLAN, please first ensure that the microcontroller is powered on correctly, then press and hold the "BLE" button and click the "RST" button. About 3 seconds after "RST" is released, "BLE" is released again. Doing this will enable Bluetooth to be turned on before WLAN.

② How to connect to the microcontroller?

Please download the "Bluetooth Serial Port Debugging Assistant" (or other applications with similar functions) on your mobile phone (or other Bluetooth device), turn on the Bluetooth switch of the device, and find the Bluetooth with the corresponding name of the microcontroller (the default is "ESP-BLE002", which can be modified) . Finally, click "Connect" to establish a Bluetooth link with the microcontroller.

③ How to modify the information saved in EEPROM?

For the measurement board, you can send messages to the microcontroller in the following format to modify certain parameters:

● “number:XXX”: Set the address of the microcontroller to XXX. XXX is a three-digit integer, such as 001

● “kind:X”: Set the measurement mode of the microcontroller to X. X is a character, which can be 'k', 'p' or 'v'. They respectively represent measuring the thermocouple, measuring the 4-20mA current and directly measuring the voltage of the ADC channel.

● “ipv4:XXX.XXX.XXX.XXX”: Set the server’s IP address in the WLAN to XXX.XXX.XXX.XXX. For example: "ipv4:192.168.0.13".

● “ssid:XXXXX”: Set the ssid to connect to WiFi, such as “ssid:MYSSID”.

● “psw:XXXXX”: Set the password to connect to WiFi, such as “psw:123456”

This information can modify one or more of them. After all transmissions are completed, send "end" to exit Bluetooth mode. At the same time, the microcontroller will save these modifications to EEPROM. After the modification is completed, please restart the microcontroller immediately for it to take effect.

④ How to modify the Bluetooth name of the microcontroller?

Open the um program (or um_noSD), find the predefined "this_BLE_no", and modify its value.

(2) Modify the sampling frequency

Open the um program (or um_noSD), and in the setup function, find "timerAlarmWrite(timer1, 1000, true);". This code indicates that sampling occurs every 1000us with a sampling frequency of 1ksps.

Then find the predefined "#define M_Size 500". This line of code indicates that it will be uploaded every 500 pieces of data collected. At a sampling frequency of 1ksps, data is sent twice per second.

Assume that you want to modify the sampling frequency to 2ksps. First modify the timer to: timerAlarmWrite(timer1, 500, true); set 500us sampling once. Then modify the predefined #define M_Size 1000 so that it still sends data every 0.5 seconds.

Note: The author does not recommend modifying the sampling frequency, because this may cause a series of problems, including: delayed data transmission, increased packet loss rate; increased memory usage of the microcontroller; decreased sampling quality, etc. Generally speaking, 1ksps can meet most experimental needs. For lower sampling frequency requirements, please obtain valid data through numerical processing; for higher sampling frequency requirements, please contact the author to customize a new microcontroller and server program: rm-f@qq.com .

(3) Custom data processing function

The microcontroller does not obtain accurate physical quantity values, but uploads the raw data of the collected voltage to the server. The processing and conversion of data are completed by measuring the javascript of the web page.

Each data packet of the microcontroller contains all the sampled data of a channel in the past 0.5s, and the last five bits are used to distinguish the data type. This data will be sent to the WebSocket server. After the WebSocket server simply processes it, it sends a data in a specific format to the HTTP server, and then the HTTP server renders them on the web page.

By default, the javascript program on the web page maps K-type thermocouple data to the range of -260°C to 1300°C according to the indexing table, maps the 4-20mA current signal to the range of 0-100MPa linearly, and maps -5~5V The voltage signal is output and plotted according to the original value.

To modify these mappings, or to redefine data processing functions, open Installation Directory \Apache24\htdocs\user_measure\script.js, locate the "sendRequest()" function, and find "for (var i = 0; i < new_data.length; i++) {… } "loop. Where new_data is a two-dimensional array and new_data[i] is the array currently being processed.

The structure of new_data is as follows:

|

“m001A” |

1023 |

1029 |

… |

36.25 |

|

“m001B” |

2083 |

2085 |

… |

“P” |

|

… |

… |

… |

… |

… |

|

“m001H” |

3096 |

3044 |

… |

“V” |

The first element of new_data[i] is the address bit, the last element is the pattern recognition bit, and the middle is valid data. If the last bit of the array is "P", it means that the microcontroller is measuring a current signal of 4-20mA; if it is "V", it means that the microcontroller is measuring a voltage of -5~5V; if it is a floating point number, it means that the microcontroller is measuring a voltage of -5~5V. A K-type thermocouple is being measured, and this floating point number represents the temperature of the cold junction.

In the valid data, -4095~4096 represents the voltage of -5~5V. Please process these data one by one according to custom rules. For arrays recording type K thermocouples, the last element should be modified to "T" after processing is completed.

The unit object on line 192 saves the units displayed when drawing in different measurement modes, and can be modified according to needs.

var unit = { //单位

P: 'MPa',

T: '°C',

V: 'V'

}

5.3 Measuring node housing

The housing of the measuring node consists of two parts: the bottom housing and the top cover. Its 3D model can be found in the Engineering Attachment under "UM Shell".

Note: The model scheme of the bottom shell is suitable for the power supply "UPS2".

(1) Bottom case

The side view of the bottom case is as follows:

①: Four platforms with through holes above the bottom shell are used to install measurement boards. The diameter of these through holes is 2.5mm, which corresponds to the four through hole positions on the PCB board. Please use a tapping wrench to create M3 threads, and then use bolts to fix the PCB on it.

②: TypeC interface location. Please solder the "TypeC-5V" PCB (see 5.1-(1)), solder the positive and negative pads to the XH2.54 terminal wire, and then insert the male end of the terminal wire into the "VIN" of the power board "UPS2" ” on the socket (pay attention to the positive and negative polarity directions). The typeC socket is inserted into the square hole shown in ② through the inside of the bottom case and fixed with glue.

③: Reserved position for antenna interface. Since the signals collected by the measurement boards are very small, they may be interfered by strong electromagnetic fields around them. Therefore, such a hole is reserved on the casing to lead out the antenna of the microcontroller.

If you need to do this, please first weld the ipex1 generation antenna base to the reserved position of the ESP32-WROVERB module, and change the soldering position of the nearby 0Ω resistor to connect it to the antenna base (Baidu). Then use ipex to SMA The IPEX end of the adapter cable is connected to the antenna base, and the SMA base end is led out from the inside of the bottom case through the hole shown in ③ and fixed with glue. Then select the appropriate antenna according to the SMA interface type and install it on the SMA base. The effect after installation is as follows:

Finally, stick tinfoil on all exposed surfaces of the top and bottom cases to shield against electromagnetic interference.

④: Reserved position for power board. Its size is basically the same as the PCB size of "UPS" or "UPS2". After the power board is welded, it can be installed in this position. For "UPS2", there are two through holes with a diameter of 3.5 on both the PCB board and the bottom case, which can be fixed with M3 bolts.

⑤: Four machine bases. Use M3 bolts to fix the bottom case. You can refer to the following specifications (some treasure):

⑥: Ship type switch installation port. The ship-type switch adopts 14*9 single-pole single-throw specifications. Press into the installation hole shown in ⑥ from the outside, and then connect the two-pin solder wires to the corresponding pads on the power supply PCB (see 5.1-(1)).

⑦: Four-digit digital tube installation port. Install the four-digit digital tube from the inside and fix it with glue. The pins are connected to the XH2.54-1x5P socket of the measurement board using an adapter cable. The corresponding pins of each pad on the PCB are as shown below. When welding, please pay attention to the corresponding relationship between the digital tube pins and the XH2.54 socket.

⑧: 18650 embedded battery box installation location. In the new power supply design ("UPS2"), the 18650 battery is no longer used, please leave this position blank. If you use a PCB power supply solution called "UPS", please install the battery box (Xubao) as shown below from the outside and fix it with glue.

(2) Top cover

The side view of the top cover is as follows:

The top cover is installed on the bottom shell. There are two rectangular hollows on the upper surface of the top cover, through which the connection terminals of the measurement board PCB and the outside world can be introduced.

6. Design and function of control nodes

6.1 PCB board

The control node contains a total of two PCB boards: power supply and control board. In addition, the normal operation of the control node also requires a synchronizer and an emergency stop circuit, each of which has a PCB board.

(1) Power supply

The power supply scheme is the same as the measurement node and will not be described again here. Since the control node does not have high requirements for power supply quality, both "UPS" and "UPS2" PCB boards can be used. The author also recommends using a PCB board called "UPS" because it supports 18650 lithium batteries and is easy to replace.

(2) Control panel

The PCB name of the control board is "USER_CTRL". It has an external power supply, which sends control signals through the microcontroller to change the state of the eight-way solid-state relay, thereby changing the conduction and disconnection of the eight terminals and the power supply. The 2D pictures of the top and bottom surfaces of the PCB are as follows:

On the top surface of the PCB, at the bottom are the installation locations for eight solid-state relays. The relay uses pin type PM5D6132 (Xubao), as shown below:

On the top surface of the PCB, at the bottom are the installation locations for eight solid-state relays. The relay uses pin type PM5D6132 (Xubao), as shown below:

The individual sockets on the top surface function identically to the measuring nodes.

n the bottom of the PCB, the one with the "DC_in" silk screen mark on the left side is the external power input terminal, which is directly connected to the DC power supply; the one with the "Trig" mark on the upper right side is the trigger signal input terminal, which is connected to the output channel of the synchronizer.

On the bottom of the PCB, eight terminals are installed on both sides. When a channel is opened, a voltage will appear between the corresponding terminals, which is about the external input voltage, and the direction is consistent with the silk screen; when the channel is closed, a high resistance state will appear between the terminals.

The functions of the "RST" and "BLE" buttons in the underside are the same as those of the measurement nodes.

There are six LED indicators installed on the bottom of the PCB, their functions are as follows:

① Ready: Lights up to indicate that the timing instructions from the server have been received, and the timing sequence can be executed immediately when the trigger signal arrives (the trigger signal will be explained below); not lit up, it means that the timing instructions from the server have not been received, and the timing instructions will not be received when the trigger signal arrives. Execution timing.

② BLE: When it lights up, it means it is in Bluetooth mode; when it does not light up, it means it has exited Bluetooth mode.

③ Low_Power: Lights up to indicate low battery power

④ Running: It lights up when the control board is powered on, and turns off when it is powered off.

⑤ Charging: Lights up to indicate charging.

⑥ Connect: Flashing means trying to connect to WiFi, solid light means connected to WiFi.

(3) Synchronizer

An experiment may need to use two or more control nodes at the same time, and they should start executing the sequence at the same time. The delay of the wireless network is often tens of milliseconds. We cannot simply send and receive instructions to start these nodes at the same time. This sometimes causes considerable deviations and even causes experimental failure.

From this, the author designed a synchronizer, which is connected to the trigger terminals of all control boards through wires. A key will be stored in the microcontroller in the synchronizer in advance; when the experiment is started, the server will send a startup password containing the key to the synchronizer (see 4.5). If the two keys match, the synchronizer will cause a rising edge on all trigger wires at the same time as a start signal for each control board. After testing, in this startup mode, the synchronization deviation of each control board does not exceed 0.3ms.

The PCB name of the synchronizer is "TRIG2", and its top and bottom surfaces are as shown below:

On the top surface, the pad with the "BAT" silk screen above is the single-cell lithium battery interface. The lithium battery leads out the wires and is directly welded to the corresponding position on the PCB. The component with four rectangular pads below it is a 5VDCDC boost board (Xuabao), as shown in the figure below:

On the bottom, there are eight trigger signal transmitting terminals on each side. They are connected in parallel with each other, and the positive and negative poles are as shown in the silk screen. When using it, it needs to be connected to the trigger receiving terminal of the control board.

On the bottom, the functions of the indicator lights and buttons are the same as those on the control panel and will not be described here.

(4) Emergency stop board

When an emergency occurs in the experiment, people can quickly press the emergency stop button to achieve protective measures. For control panels, in an emergency, some channels need to be closed and the rest need to be left open.

The PCB name of the emergency stop board is "EMER", and its schematic diagram is as follows.

In order to make the emergency stop work, please distinguish in advance the channels that need to be closed and opened on each control board in the emergency stop state. Then perform the following operations on the power supply of each control board and the above-mentioned channels that need to be opened:

a. Solder both ends of the DC power supply to the +24V and GND connection locations respectively.

b. Lead the wire from GND as the negative pole of the external power supply of each control board; lead the wire from the pad shown in ② as the positive pole of the external power supply of each control board.

c. Select two normally open pins of an emergency stop switch, and solder one end to the +24V pad and the other end to the pad shown in ①.

d. The emergency stop board is surrounded by seven green terminal blocks. For the channel that needs to be closed in the emergency stop state, please connect the negative pole of the channel directly to the load, connect its positive pole to the positive pole of the green terminal on the emergency stop board, and then connect the negative lead of the green terminal on the emergency stop board to load. Looking down from the top, in a clockwise direction, the two wiring ports of each green terminal are positive and negative. See 6.1-(5) for specific wiring diagrams.

e. Press the emergency stop switch in an emergency state to disconnect all external voltages of all control boards. Channels not connected to the emergency stop board will be in a high-impedance state, and channels connected to the emergency stop board will output power supply voltage.

Note: When selecting wires, especially power wires, please pay attention to the load current on the wire and select the appropriate wire diameter based on the allowable temperature rise.

Note: An emergency stop board supports up to seven channels that need to be opened. If more emergency stop boards need to work in coordination, please connect them to the same power supply and emergency stop switch.

Note: The pad of the emergency stop board is relatively compact, please be careful to avoid short circuit caused by wire contact.

(5) Connection methods of control board, emergency stop board, trigger, power supply, emergency stop switch and load

As shown below (the microcontroller and its power supply have been omitted):

In the figure, loads 1 and 3 need to be powered on in an emergency state, and loads 2 and 4 need to be shut down in an emergency state.

Since the author used a 24V DC power supply when debugging, some pins have "24V" related network names. In fact, the input range of the external power supply is 5-30VDC, depending on the load.

6.2 Microcontroller

Both the control board and the synchronizer use the ESP-WROOM32 microcontroller, as shown in the picture below (a treasure).

Both programs are compiled by ArduinoIDE. The Websocket library file can be found in the attachment "arduinoWebsockets-master".

6.2.1 Control board microcontroller program

The microcontroller program of the control board is USER_CONTROL.ino. Since the Bluetooth and WiFi libraries are called in the program, which requires a large memory footprint, please adjust the partition mode to Huge_APP.

The following instructions are given for the program of the microcontroller:

(1) Timing trigger mechanism

As stated in 6.1-(3). If the control board wants to start the sequence, it must first send a message to the microcontroller through the server to turn it into a "waiting for trigger state" (see 4.5, the "Ready" indicator light will light up at this time). Then operate the synchronizer to generate a specific level signal (trigger signal) and pass it to the trigger end of the control board.

The trigger terminal is connected to a certain pin in the microcontroller. The microcontroller sets an interrupt for the trigger signal. After the trigger signal arrives, the microcontroller immediately begins to execute the analyzed timing sequence until all timing sequences are executed. Subsequently, the Ready indicator light goes out, the microcontroller waits for 1s and then the status is restored, and the timing can be re-edited and sent to it.

The function of manually changing the status of a certain channel shown in 4.3-(2) is valid at any time except timing execution of the microcontroller. In other words, manual control through the web page does not need to ensure that the microcontroller is in the "waiting for trigger state", but timing startup does.

(2) Bluetooth function

The Bluetooth function of the control board microcontroller is basically the same as that of the measurement board, and supports the following format messages:

● “number:XXX”

● “ipv4:XXX.XXX.XXX.XXX”

● “ssid:XXXX”

● "psw:XXXXXXXX”

See 5.2-(1) for details.

6.2.2 Synchronizer microcontroller program

The microcontroller program of the synchronizer is TRIG2.ino. Since the Bluetooth and WiFi libraries are called in the program, which requires a large memory footprint, please adjust the partition mode to Huge_APP.

The following instructions are given for the program of the microcontroller:

(1) Bluetooth function

In addition to the functions described in 6.2.1-(2), the synchronizer's microcontroller also supports saving and modifying the startup key. The specific message format is:

sce:XXXXXXXX

NOTE: The startup key must be eight visible characters. If the key length entered by Bluetooth is greater than 8, the first eight digits will be intercepted and saved as the key; if it is less than 8, an error will be reported and the key will be discarded.

(2) Participate in the network

The synchronizer is similar to the control board. It sets its own address through the corresponding value of the number parameter in the EEPROM and joins the WebSocket network.

The author recommends setting the address of the synchronizer to 080-089 and the address of the control board to 001-079 to distinguish them.

6.3 3D shell

6.3.1 Control panel housing

The side view of the control panel housing is as follows:

Most of the design of the housing is similar to the bottom housing of the 5.3-(1) measurement node, and will only be briefly described here:

① Four 2.5mm diameter through holes, please tap M3, for installing the control board PCB

②Through hole of machine foot, diameter 3.5mm

③Ship type switch installation port, 14*9mm

④ The embedded battery box installation port is installed from the outside and bonded with glue.

⑤ LED four-digit digital tube installation port, install it from the inside and bond it with glue

⑥ Power board installation location. Either "UPS" or "UPS2" power strip allows the microcontroller to work normally. If the PCB of "UPS2" is used, the battery box shown in ④ does not need to be installed.

⑦ TypeC interface installation position, install from the inside and bond with glue.

Since most of the signals in the control panel are digital signals and have strong anti-interference ability, there is generally no need for special protection against electromagnetic waves in the air.

6.3.2 Synchronizer housing

The side view of the synchronizer housing is as follows:

Most of its design is similar to the bottom shell design of the 5.3-(1) measurement node, and will only be briefly described here:

① Four through holes with a diameter of 2.5mm, used to install the synchronizer PCB. Please tap M3 to fix the PCB with bolts.

②Through hole of machine foot, diameter 3.5mm

③Ship type switch installation port, 14*9mm

④ The embedded battery box installation port is installed from the outside and bonded with glue.

There are some rectangular holes around the synchronizer, which are used to facilitate the installation of PCB and microcontroller. When installing, please complete all welding except the switch first, install the PCB from the outside of the top surface of the casing, insert the microcontroller from the inside of the casing, and then install the battery box. Finally, run the wire from the switch hole, solder it into the pins of the switch on the outside of the case, and install the switch.

Note: The synchronizer does not support charging. If the 18650 battery is exhausted, please remove it and recharge it.

6.3.3 Emergency stop panel housing

Due to the large number of wiring connections and complex usage of the emergency stop board, a 3D housing has not been designed yet. The project will be updated in the future to supplement this.

7. How to use this system?

(1) Preparation work:

● Create reliable WiFi signals for the experimental area;

● Read project instructions, prototype and solder all PCB boards

● The shell in the 3D printed accessories is boring to buy, and the measurement nodes, control nodes and synchronizers are assembled.

● Refer to the “3.3V” pin of the microcontroller base in the PCB file and choose a reasonable direction to insert the microcontroller.

(2) Start measurement:

① Power on all measurement nodes that need to be used, connect the sensors, and then configure the node and network information through Bluetooth (please ignore it if it has been configured) (see 5.2-(1)).

② Modify the data processing function as required (see 5.2-(3)), and then start the server.

③Open the auxiliary program and connect to the server.

④ In the "Measurement Node Management" tab of the auxiliary program, check the number of online links and their network delays.

⑤ After confirming that all nodes are online, click "Execute Preparation" to start measurement.

⑥Open localhost/user_measure in the browser to view real-time data. For other users in the WLAN who are not the server, replace localhost with the address of the server in the WLAN, for example: 192.168.43.5/user_measure

⑦After the experiment, click "Execute Preparation" again to stop the measurement.

⑧Enter the "Installation Directory\dataget\RCV" folder and find the corresponding log file (named by time, which will be regenerated every time the server is started), which contains all the original data collected.

⑨ Find the "work_dir" folder in the attachment, compile the "data_deal.cpp" in it, and obtain "data_deal.exe". Copy the log file in ⑧ to the "work_dir" folder, and then double-click "data_deal.exe". After a period of time, a csv file with the same name as the log will be automatically generated.

⑩Open the csv file, which saves all the collected data from the beginning to the end of the experiment, and has been automatically converted into physical quantity values.

Note: work_dir is a data processing program, written in C++, and needs to reference nlohmann/json.hpp (see the attachment "json_develop", add the "single_include" folder to the reference directory). The processing functions for K-type thermocouple, 4-20mA current and voltage signals in the program are del_T, del_P and del_V respectively. The parameters passed in by these functions are the collected original voltage data (-4095~4096, mapped to -5~5V), and the return value is the value of the processed physical quantity. For the processing function of K-type thermocouple, the program has a temperature-voltage scale table, and the interpolation result is basically accurate. The author does not recommend modification.

⑪If the signal of the microcontroller is lost during the experiment, please pull out the SD card of the measurement board and insert it into the computer card reader. The "dataRCV" directory in the SD card saves all historical measurement data, and its file name is "mXXX.txt". The one with a larger number has a later collection time.

Note: Naming errors may occur when there are too many historical files accumulated. The author recommends backing up the data in the SD card after each experiment, then clearing the "dataRCV" folder, and modifying the content of file_no.txt to "0" (no quotes, no line breaks, only a number 0).

(3) Start control:

① Power on all control nodes and synchronizers that need to be used, wire and connect the load as shown in 6.1-(5). Then configure the network information of the control nodes and synchronizers through Bluetooth (please ignore if they have been configured), and The synchronizer's Bluetooth configures the startup key for this experiment (see 6.2).

② If timing control is used

a. Open the auxiliary program and connect to the server

b. Enter the "Timing Edit" tab to configure the timing of each channel and save the file locally.

c. Enter the "Timing View" tab to open the timing file, check the timing graphics, and send it to the server (see 4.5).

d. Enter the "Control Node Management" tab and check the number of online links and their network latency. Click "Start Injection" to send the timing file to each node.

e. Click "Execution Preparation" to put each node into the waiting trigger state.

f. Enter the "Sequence Start" tab, enter the startup key, and click "Start". The execution sequence starts after 5 seconds.

g. If you encounter an emergency, please press the emergency stop button immediately. The channel connected to the emergency stop board will be opened instantly, and the other channels will be closed instantly.

③ If manual control is used

a. Go to "localhost/user_control" through the browser, register an account and log in.

b. Add the desired control channel name. The name is in the format "[s0XX]N", for example [s009]A. (See 4.3-(2))

c. Control the opening and closing of the channel by clicking "ON/OFF".

(1) The power supply test is not sufficient yet, and the power supply design may be modified later.

(2) The control server will lock the user's login status, and there may be a problem that the user cannot log in again after logging out. This problem is difficult to reproduce. Try to avoid closing web pages by killing processes to reduce the occurrence of this problem.

(3) There may be an error in the SD card file name on the measurement board. This problem is difficult to reproduce. Please clean up the SD card files in time.

I am a novice in electrical design, and many designs need to be optimized.

If you have any questions, please contact: rm-f@qq.com.

The open source project will be updated from time to time, and the author will publish an update log in the comment area. Welcome to pay attention.

============END============

Designed by starsky2019 (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment