Completed

CompletedRP2040 six-axis 3D printer control panel

PRO RP2040 six-axis 3D printer control panel

RP2040 six-axis 3D printer control panel

License

:GPL 3.0

Description

Project Description

This project is a six-axis 3D printer control board, and it is an integrated control board for the upper and lower machines. Both the upper and lower machines use the open source klipper firmware.

The onboard six-channel TMC2209 driver chip can drive six-channel stepper motors, as well as other hot beds, hot ends, thermal sensors, and fans.

At the same time, there are 3 USB interfaces onboard, which can be connected to other USB devices.

Reference video: https://www.bilibili.com/video/BV1Qp4y1E7Zq/?share_source=copy_web&vd_source=65a85cc2101a5ea7d90341ab7d3ac406

Klipper reference documentation: http://www.klipper3d.org/zh/Overview.html

Klipper Open Source Link: https://github.com/Klipper3d/klipper/

Open Source Agreement

GPL 3.0.

Project Related Functions

This project’s 3D printer control panel has the following functions:

1. Onboard 6-channel driver chip can control 6-channel stepper motors;

2. Equipped with hot bed, hot end interface, and 3-way thermal interface;

3. 3-way controllable fan interface;

4. 3-way limit interface;

5. 1-way probe or consumable detection interface;

6. 4-way USB interface, of which the back interface is the interface for connecting to the host computer and can be connected to portable WiFi, and 1-way interface is the XH2.54*4P interface, which can be connected to the tool head;

7. 1 type-c interface, used to flash the lower computer, or use USB mode to connect to the lower computer;

8. Onboard serial port chip, the upper computer uses the serial port to connect to the lower computer, avoiding the problem of unrecognizability when the RP2040 is restarted multiple times in USB mode.

Project Properties

This project was made public for the first time and is my original project. The project has not won any awards in other competitions.

Project Progress

Schematic drawing (completed)

PCB drawing (completed)

Hardware production (completed)

Configuration writing (completed)

Verification (Complete)

Shell (finished)

Design Principles

The MCU of the lower computer in this project is based on RP2040. It controls the stepper motor, hot bed, hot end and fan by connecting motor driver chips, MOS tubes and other chips; it collects temperature through the chip ADC interface; both the upper and lower computers use the currently more mainstream open source klipper system. , the upper computer connects to the lower computer MCU through the serial port, and controls the 3D printer through klipper.

RP2040 Minimal System.

USB to serial port chip, using serial port connection is more stable.

Power input and conversion 3.3V to supply power to MCU.

Stepper motor drive circuit.

Hot end heating bed control circuit.

Thermal interface, used to obtain the temperature of the hot end heating bed.

Fan control circuit, used for duct cooling, model cooling, and motherboard cooling.

Probe and limit circuit.

USB HUB circuit, expands multiple USB interfaces, used to connect peripherals.

Indicator circuit, used to determine the output status of each power supply.

Interface and wiring guidance.

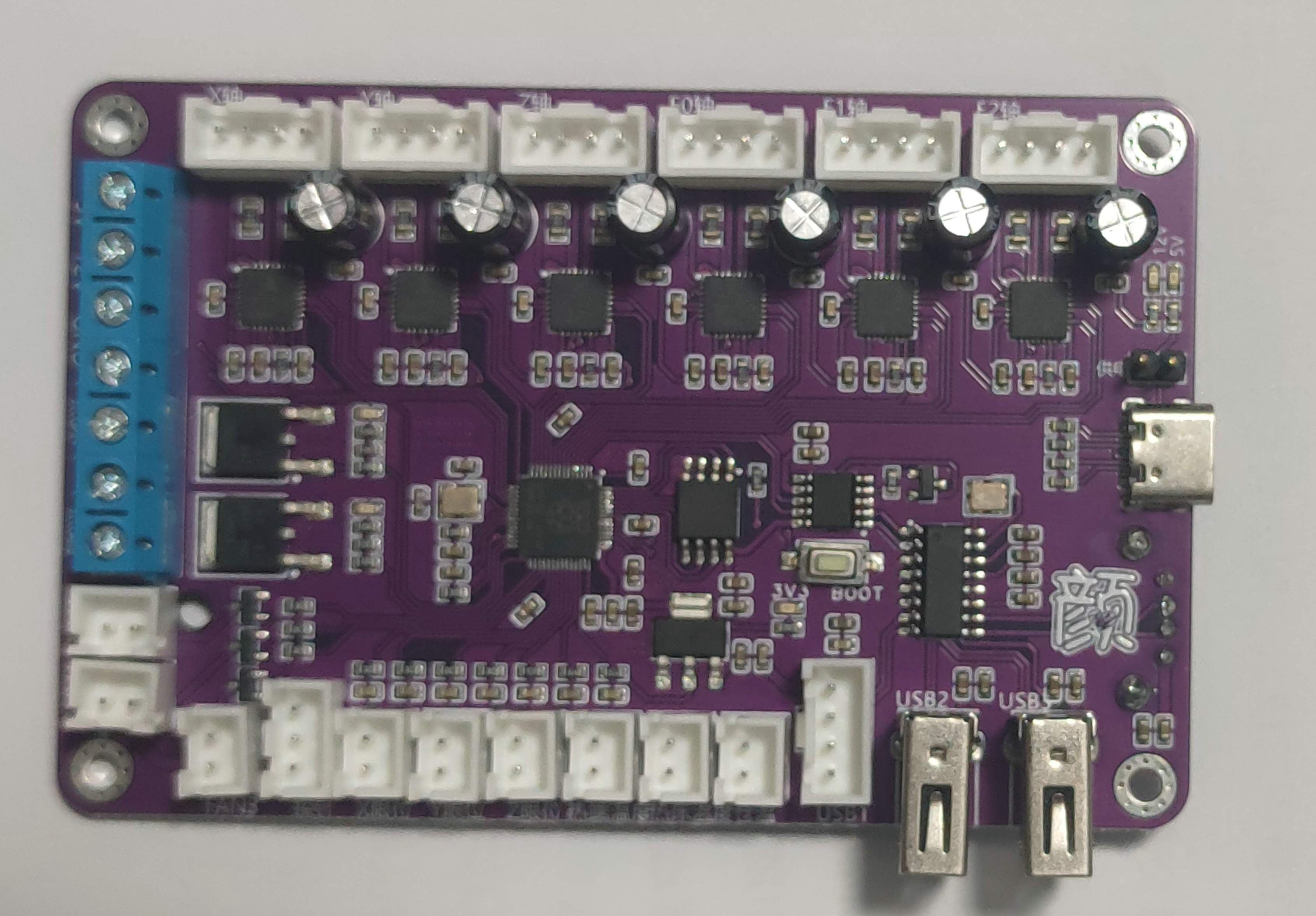

Physical Display

Front:

Reverse side:

To install into the enclosure:

Connecting cables:

Install the printer:

Install the upper cover:

Designed by yanshimi (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor.Intellectual Property Statement & Reproduction Instructions

This is an open-source hardware project. All intellectual property rights belong to the creator. The project is shared on the platform for learning, communication, and research only; any commercial use is prohibited. If your intellectual property rights are infringed on EasyEDA, please notify us by submitting relevant materials in accordance with the Rules for Complaints and Appeals of IPR Infringement.

Users must independently verify the circuit design and suitability when replicating this project. All risks and consequences are borne by the user, and the platform assumes no liability.

Empty

Empty

Comment