Completed

CompletedOER_Charge Super thin! Desktop 140W/65W Super Fast charge

PRO OER_Charge Super thin! Desktop 140W/65W Super Fast charge

OER_Charge Super thin! Desktop 140W/65W Super Fast charge

License

:GPL 3.0

Description

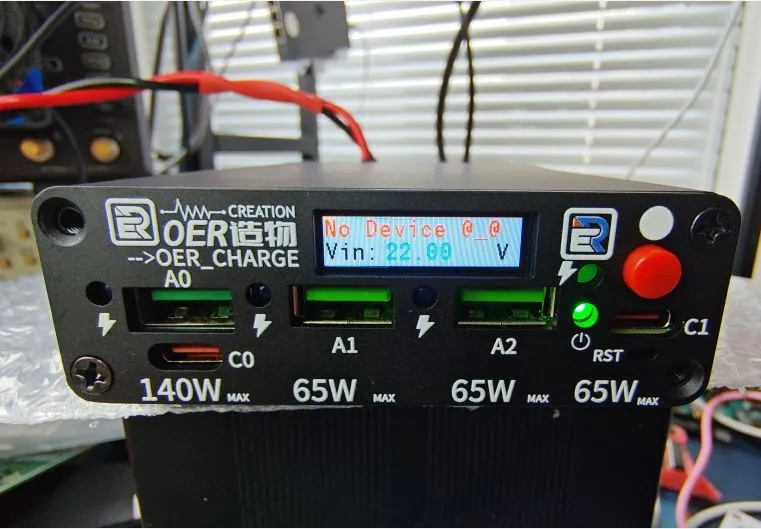

OER_Charge is a sub-module under the OER_WorkStation system (OER desktop workstation, in progress) and is responsible for the basic fast charging function (12V input) of the OER_WorkStation.

Ultra-thin, ultra-thin, ultra-thin! Multi-bite, multi-bite, multi-bite!

OER_Charge module input methods are:

(1) TYPE-C PD decoy 20V.

(2) XT30 connector input (24V max).

(3) PCIE interface mode (limited to OER_WorkStation connection).

OER_Charge maximum design power is 140W fast charging*1, 65W fast charging*3.

The interfaces are: USB-A interface*3, TYPE-C interface*2. The theoretical maximum output power is 140W + 65W + 65W + 65W (24V input). In the OER_WorkStation system, due to the input voltage limitation, the maximum is 60W+36W (so the basic fast charging component), and the display interface is reserved to digitize the charging process and add other functions. There is also a OER_HighCHG (full power fast charging module) in the research module, which will try its best to achieve full power, but will reduce the number of output ports accordingly.

Note: Please pay attention to the use of capacitors that meet the withstand voltage value to avoid dangerous conditions.

Thanks to the pioneering and dedication of our predecessors, the engineering, structural design, and programming are all open source.

Material:

(1) PCBA: Jialichuang PCB+SMT

(2) Shell: Jialichuang aluminum alloy shell

(3) Screen: Huang Baokai Zhongjingyuan 0.99 inch display high-definition IPS display strip screen GC9D01 driver 40x160 (https://item.taobao.com/item.htm?_u=31l526mr5fb8&id=677743417274&spm=a1z09.2.0.0.17df2e8dItAhb6).

(4) Screen transfer backplane (uploaded by open source): https://oshwhub.com/ulysse/t01ips099

(5) DCDC step-down plate (uploaded by open source): https://oshwhub.com/ulysse/t02dcdn

Reference to previous designs:

① https://oshwhub.com/wqlll/sw3538

② https://oshwhub.com/w.rh/open-source-147-color-screen-six-way-sw3538-sw3526-ina226

1 Completed features:

(1) Basic functions of five-way fast charging.

(2) The basic input voltage, output voltage, and output current of each fast charge are collected.

(3) The actual maximum output of 140W is 20V@6.37A and 122.38W (7A is estimated because my test load cannot be triggered without the E-markr function)

(4) The thickness of the whole machine is 28mm, ultra-thin and ultra-thin!!

2.To be continued & remaining issues.

(1) Screen GUI, the resolution of the screen is too small, and it takes a lot of brains to do UI, so it is temporarily shelved, but uGUI has been transplanted, if there is time to continue to improve it in the future.

②SW3538 has an ADC problem: After I set the maximum power in register mode, the maximum power can open 140W mode, but at this time, the ADC reading of SW3538 is paralyzed, and I have chewed the register manual many times.

I have not found the problem, so I have temporarily shelved it. I have asked FAE through my friends, but I have not replied yet.

(3) The key hole of the structure is slightly larger, and the button will fall out, so prepare a 3D printed button hat.

(4) The key function part continues to be optimized, and the program functions can be more abundant.

3.The development process (smelly and long, if you are interested, you can browse):

1. 20240930 Completion of board and SMT (the actual audit passed on October 9, and the board was obtained on the 15th), and the structural design was prepared.

2. 241007 The first version of the structural shell design is mainly used for the shell when the module is used alone, and the shell design software is used.

3. 241008 Interactive display module PCB design is used to display parameters with 0.99 inch screen.

4. 241009 Stand-alone DCDC step-down module PCB design is used for the power supply of the control part when the OER_Charge is used alone.

5. 241014 Solder the T01 screen adapter board and T02DCDC buck plate, and perform load test.

6. 241008-241014 Use SW software to gradually improve the overall structure of the design, with preliminary appearance, heat sink, screen bracket, fixed bracket, multi-board card fit.

7. 241008-241015 Motherboard test and power-on function verification.

(1) SW3526's USB-A port fast charging detection

(2) SW3526 USB-A port fast charging power test

8. 241017-241018 MCU program test (these two days are serious overtime, there is no time to advance)

Successfully run the MCU, build the program framework, and light up the LCD.

9. 241018-241020 Compare the data sheet and the official data package, start writing the driver files of SW3538 and SW3626 (github has not flipped around, write it yourself), register definition, I2C test, etc. Complete basic functions such as chip detection, power detection, input and output voltage and current reading (and will continue to be optimized)

The I2C address of the SW3526 cannot be configured, and I use 3 more chips, so I use the I2C multi-channel switching chip, and TCA9544 will need to cut the I2C corresponding channel before communication.

10. 241018-241022 Continue to optimize the structural design and shell, use SOLIDWORKS and Jialichuang shell design to change and change, and the shell has reached the 18th version.

(1) JLC aluminum alloy gold shell

②solidworks structural design

(3) 3D printed shell and various support structures are tested together

11. 241022-241027 Wait for the aluminum alloy shell to come back from proofing, continue to write driver functions, and carry out UI design.

(1) The SW35XX chip driver is basically completed, and the basic data is all read and tested normally (50+ registers are hand-stroked, just for these few one-click use functions)

( 2) The driver given by the LCD driver manufacturer can be used, but it is too cold, the function is poor, and the effect is not good. Find a driver code on GITHUB and start the transplant journey.

Taobao sellers offer:

Brother Mao Zi wrote:

One night the transplant was successful and driven:

11. 241028 Continue to port the LCD driver function, and complete the display of letters, font size, and letters in any direction.

The shell has been shipped, waiting for the courier to come back.

12. 241029 After transplanting the LCD driver, I found that I might have to use a GUI interface, but LVGL and other GUI programs are running on the small piece of STM32F103C8T6, just like a grandmother's anti-cement - slag on the side of the card, and then I went to find a lightweight GUI, so I found uGUI, a lightweight GUI from 10 years ago, and began to transplant.

①uGUI address:http://embeddedlightning.com/ugui/ github:https://github.com/achimdoebler/UGUI

(2) Start the transplant

(3) It took one night to transplant successfully

13 . 20241030 JLC shell arrived, and the assembly began

14 . 20241031 Continue to write some of the driver functions to simply display some information

①SW3526 VIN:22V,VOUT:20V,IOUT:3.2A

15 . 20241101-20241103 Test and function writing.。

(1) 20V@6.37A test.

Heating situation: (flat copper wire inductance: I want to be hot and fried!! )

(2) Input voltage acquisition accuracy

(3) The interface automatically switches with the plugged device (no device prompt, there is a configuration to automatically identify the fast charging port)

No Device:

Device C0:

Device A0:

Device A1:

Device A2:

Device C1:

16 . No end, no need to sprinkle flowers (continuous optimization)

Designed by OER造物 (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment