Completed

CompletedMobile intelligent environmental detection vehicle

PRO Mobile intelligent environmental detection vehicle

Mobile intelligent environmental detection vehicle

License

:GPL 3.0

Description

Preface

With the acceleration of global industrialization and the continuous expansion of urbanization, environmental issues have become one of the major challenges facing today's society. Various environmental problems such as air pollution, water pollution, and soil pollution not only pose a serious threat to human health, but also cause irreversible damage to ecological balance. In such a severe situation, environmental monitoring, as the basic work and important means of environmental protection, its accuracy, comprehensiveness, and timeliness are particularly critical.

Traditional environmental monitoring methods mainly rely on fixed monitoring stations. Although these stations can obtain environmental data of specific locations to a certain extent, they have obvious limitations. The layout of fixed stations is relatively sparse, making it difficult to cover all areas that need to be monitored, especially in areas with complex terrain, inconvenient transportation, or vast areas, which can easily form monitoring blind spots. Moreover, the monitoring equipment of fixed stations usually can only obtain local environmental information of their location, making it difficult to fully grasp the dynamic changes and differences in the environment within the region, and cannot meet the needs of fine-grained monitoring and management of the environment.

This study is based on the intelligent flow environment detection vehicle designed and developed by ESP32, aiming to overcome the shortcomings of traditional fixed monitoring methods. The vehicle can move flexibly in different environmental scenarios and conduct environmental Data Acquisition in every corner, greatly expanding the scope and flexibility of environmental monitoring. By integrating various advanced sensors, such as BMP280 for accurate collection of temperature, humidity, and air pressure data, the ESP32cam camera can capture intuitive image information. Combined with weather forecast information obtained through network APIs, it achieves comprehensive collection and analysis of multi-source data, providing rich data support for comprehensive and accurate understanding of environmental conditions. In addition, with the help of servers and mobile apps, efficient data transmission and remote monitoring have been achieved. Staff can grasp the environmental information collected by the inspection vehicle anytime and anywhere, timely discover environmental problems, and make corresponding decisions. The vehicle also has remote control function, which facilitates operation in special environments or dangerous areas, further improving the practicality and adaptability of the inspection vehicle. At the same time, the equipped high-horsepower mowing motor enables the inspection vehicle to undertake weeding tasks on the basis of environmental monitoring, and can be applied to comprehensive environmental maintenance of parks, lawns and other places, improving the versatility and resource utilization rate of the equipment. It has extremely important practical significance in the field of environmental monitoring and site maintenance, and is expected to promote related industries to move towards intelligence and efficiency.

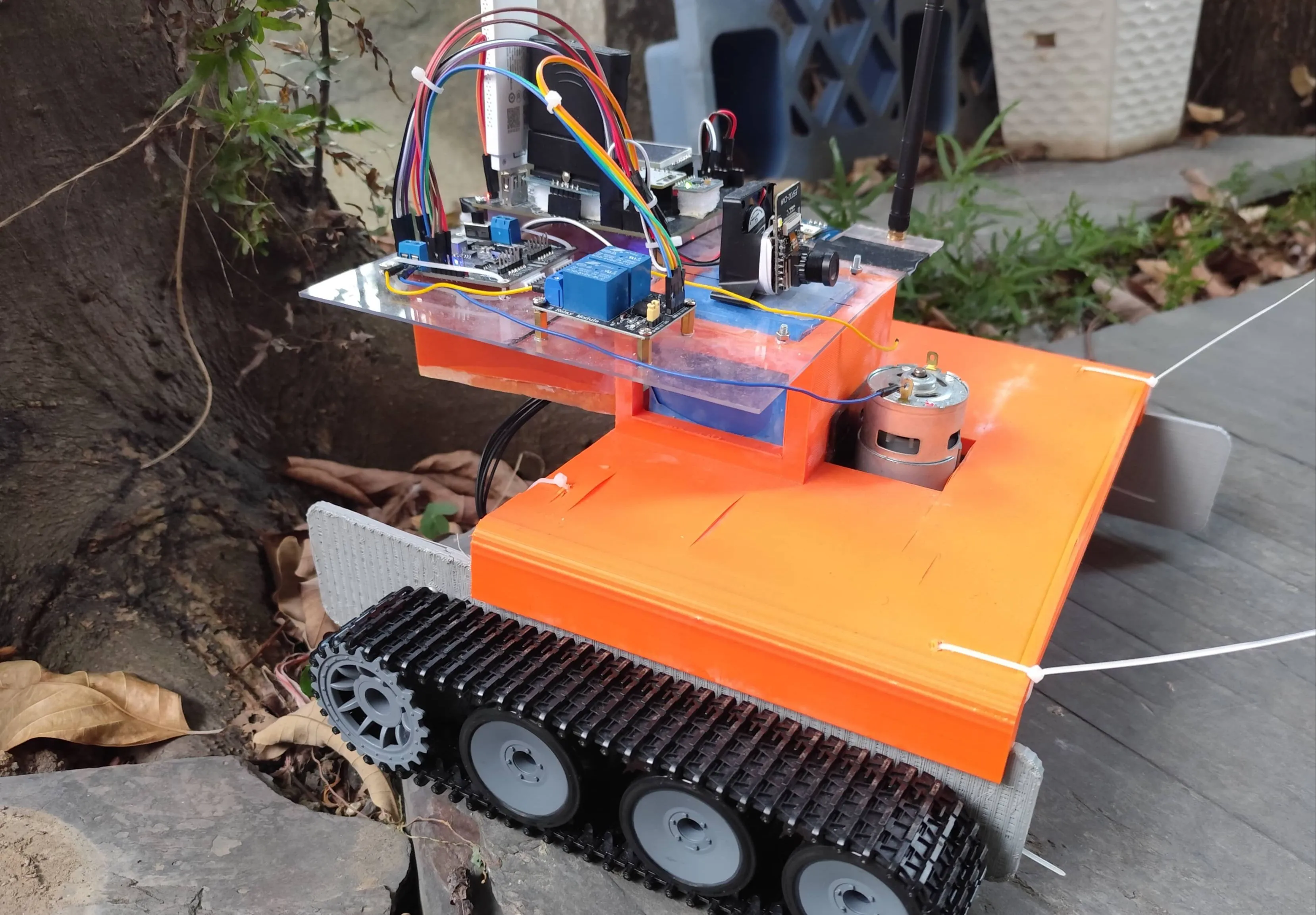

Project display

(1) Vehicle display

(2) APP display

(3) Server logs

(4) MQTT logs

Project features

(1) Remote control

Using PS2 wireless controller to manually control the tracked vehicle, with a wireless frequency of 2.4GHz, stable connection, and a distance of up to 10 meters. The button function is rich, which can control the direction while starting the mowing motor or recording data in real time.

(2) Mobile weather station

Using GY-39 sensor, low cost, air pressure, temperature and humidity, light intensity, sensor module. Also using Autonavi weather API, data source is China Meteorological Administration.

Real-time temperature and humidity conditions, weather conditions, air pressure, and light intensity can be obtained, and the data can be summarized on the server for Data Analysis.

Analyze the weather status curve, which has been fed back in real time in the APP, and you can get the outdoor weather status without leaving home.

(3) APP side (simplified version)

Developed a simplified version of the APP, although the User Interface Design is a mess, it can meet the basic functions.

APP control uses MQTT protocol, with low latency and low fault tolerance.

Autonomous driving uses a fixed path to complete the entire journey within the corresponding graph.

(4) Mowing the lawn

Using a 12V 755 motor, this is a lithium-ion lawn mower that can be used for weeding by high-speed rotation with blades.

Note: This project uses safe nylon blades, but the sharpness of the nylon blades is not enough, so if used on the product, it is recommended to use metal blades!

When using a metal blade, be sure to solder the nut or apply strong glue, otherwise it is very dangerous!

Hardware solution

(1) Main control chip

Using two ESP32-WROOM-32 modules.

Module 1 controls the motor and is paired with the MPU6050 gyroscope module for PID control of the motor, thereby driving the track movement.

Module 2 is responsible for data processing and transmission, transmitting data to the API, and then the server performs data processing and feedback to the APP and microcontroller.

The ESP32 WROOM 32 processor has powerful processing capabilities. The dual-core architecture and high clock frequency can efficiently handle complex tasks and large amounts of data. The rich peripheral interfaces cover various digital, analog, and special sensor interfaces, which can easily connect various sensors and actuators. Excellent wireless communication functions support Wi-Fi and Bluetooth, making it easy to transmit remote data and interact with peripheral devices.

- Using Xtensa dual-core 32-bit LX6 microprocessor, with two independent CPU cores that can be controlled separately, the clock frequency can reach up to 240MHz, and the computing power can reach 600DMIPS

- On-chip integrated 4MB flash memory for program and data storage.

- Integrated 802.11b/g/n HT40 Wi-Fi transceiver, supports WiFi direct connection.

- Supports Bluetooth 4.2, including classic Bluetooth and low-power Bluetooth, suitable for various IoT applications.

- It has 18 12-bit analog-to-digital converter (ADC) input channels, which can obtain analog readings from 0 to 4095, corresponding to a voltage range of 0V to 3.3V; it also has 2 8-bit DAC channels, which can convert digital signals into analog voltage signals for output.

- Equipped with various digital interfaces such as SPI, I2C, UART, and I2S, it is convenient to connect various sensors, actuators, and external devices.

(2) Screen visualization

The screen is not too important, because the crawler car is mainly focused on intelligence, and the importance of using the screen is not as great as that of the APP, which can be used or not

The project uses two common screens, OLED and TFT_LCD, equivalent to a main screen and a secondary screen

①1.8 inch TFT_LCD

It can be used to display real-time weather station information, as well as display the connection status of the microcontroller, APP, and server, feedback the microcontroller status, and alarm information.

② 0.96 inch OLED

The current idea of the secondary screen is to display the QR code of product information, as well as the communication status of two ESP32s, and display heartbeat information.

(3) Environmental detection chip

Using the GY-39 module, this module integrates BMP280 and MAX44009 sensors. This project mainly uses BMP280 and adopts UART communication, which can collect pressure, temperature, humidity, and altitude information. The module has very good stability and anti-interference ability and can be used in complex environments.

- Accurately measuring atmospheric pressure can also calculate altitude by measuring changes in pressure, and temperature can also be measured

- Pressure resolution up to 0.18 Pa, altitude resolution up to 1.5 meters, barometric measurement range from 300 hPa to 1100 hPa, covering altitudes from sea level to approximately 9,000 meters

- The working voltage is between 1.71V and 3.6V, and the working temperature range is -40 ℃ to + 85 ℃, which can adapt to various harsh environments

- Its working temperature range is wide, and it can work stably in the range of -40 ℃ to + 85 ℃, and can maintain stable performance in agricultural outdoor environments or industrial high and low temperature scenes

- The internal integration of calibration and compensation algorithms can automatically calibrate and compensate for factors such as temperature and pressure, reducing the impact of environmental factors on measurement results and improving measurement accuracy and stability.

- Equipped with digital filtering function, it can filter and process the collected pressure and temperature data, effectively removing noise and interference, making the data smoother and more stable.

(4) Motor drive module

The module uses the AT8236 chip, a dual-channel DC motor driver chip that can drive two DC motors at the same time, with high driving ability and efficiency. It can realize functions such as forward rotation, reverse rotation, and speed regulation of the motor, and is equipped with various protection functions such as overcurrent protection and overheating protection, which improves the reliability and safety of motor driving.

- High-performance power MOSFET tubes are used as driving components, which have the characteristics of low on-resistance and high switching speed, which can effectively reduce power loss during motor driving, reduce heat generation, and improve driving efficiency and stability.

- It is equipped with various protection circuits such as overcurrent protection, overheat protection, and undervoltage protection. When the motor experiences overload or short circuit causing excessive current, the overcurrent protection circuit will cut off the motor power supply in time to prevent damage to the chip and motor. When the chip temperature is too high, the overheat protection circuit will reduce the motor's driving ability or stop driving to avoid damage to the chip due to overheating. When the power supply voltage is below a certain threshold, the undervoltage protection circuit will prevent the chip from working to ensure the safety and stability of the motor drive.

- When used in conjunction with a microcontroller, it can accurately control the duty cycle of the PWM signal, thereby achieving precise adjustment of the motor speed. By adjusting the duty cycle of the PWM signal, linear changes in motor speed can be achieved over a wide range, meeting the control requirements of motor speed in different application scenarios.

- In the process of chip design, electromagnetic interference issues were fully considered, and various anti-interference measures were adopted, such as optimizing circuit layout and increasing filter capacitors, so that it can work stably in complex electromagnetic environments and is not easily affected by external interference signals.

(5) Manual remote control module

The PS2 controller is used for manual control, with two parts: the receiver and the controller, simple operation, multiple function buttons, transmission distance of about 10 meters, and good stability in connection.

- The buttons and joysticks of the PS2 controller have the characteristics of high sensitivity and fast response, which can enable agricultural robots to quickly execute the operator's instructions, achieve precise agricultural operations, reduce operation errors, and improve operation quality and efficiency.

- The PS2 controller technology is mature, the structure is relatively simple, and the maintenance and repair costs are low. Even if there is a malfunction, it is easy to find professional maintenance personnel or perform simple repairs by oneself

(6) Camera module

Using the ESP32-CAM module, which is based on the ESP32-S chip and paired with the OV3660 camera, it can automatically capture images and transmit them to the server through HTTP communication of the ESP32-S for remote monitoring. Due to the huge heat generated by the ESP32-CAM during operation, a Mini fan is installed for heat dissipation for stability and security.

- Using a low-power dual-core 32-bit CPU with a main frequency of up to 240MHz and a computing power of up to 600 DMIPS, it has a built-in 4MB PSRAM, providing powerful computing and storage capabilities for fast image processing and storage.

- OV3660 camera, 3 million pixels, 1/5 inch.

- Integrated Wi-Fi and Bluetooth functions, supporting 802.11b/g/n standards, image data can be transmitted to the cloud or other devices through Wi-Fi for remote monitoring and control.

(7) Relay module

The project uses a 12V mowing motor for mowing, so based on the safety of the mower and the whole, a relay is used to control the mowing motor, and the relay is controlled by the main control chip to achieve isolation and safety control of the motor.

- When the mowing motor is started directly, it will generate a large starting current, which may cause damage to the winding and insulation of the motor, affecting the service life of the motor. Relays can be used in conjunction with devices such as step-down start and soft start. By controlling the voltage or current during the starting process, the motor can start smoothly, reduce the impact of the starting current on the motor, and thus extend the service life of the motor.

- During the mowing process, it may be necessary to frequently start and stop the motor. The relay can quickly respond to control signals, achieve frequent on/off of the motor, and will not cause excessive damage to the mechanical structure and electrical performance of the motor. In contrast, if the motor is frequently operated directly through manual switching, it may cause additional damage to the motor due to improper operation or switch life issues.

(8) Drive motor

Using a deceleration motor with a reduction ratio of 1:56, model 520, rated voltage 12V.

Intelligent vehicles with agricultural and industrial performance, choosing a 1:56 reduction ratio crawler type is the most suitable, with the best load-bearing capacity and stability, can be used in complex environments and stable operation, and is not easy to cause hardware errors due to bumps.

Overall design

(1) Frame design

The frame is 3D printed and is divided into two parts, the main part is the frame body, and the secondary part is the fixed frame for fixing the track.

By using 3D printing, the lightweight of the frame can be achieved while ensuring its strength. This is of great significance for improving the energy efficiency, cruising range, and handling performance of intelligent vehicles.

According to the one-month test of this project, it has been verified that the strength of the 3D printed frame can complete basic environmental monitoring and still have good fluidity in harsh environments.

(2) Track design

The track adopts 2 transmission wheels and 2 load-bearing wheels, with a track width of 45mm. Both the track and the wheel are made of high-strength plastic to ensure stability and overall lightweight.

The appropriate track width and wheels can ensure smooth overall operation and operation in complex scenarios.

(3) Supporting design

All smart hardware is placed on a 200 * 200mm transparent acrylic board, fixed with 4 M3 screws, and there is support under the acrylic board to maintain the stability and safety of the hardware during the movement of the smart car.

Hardware design

(1) Schematic design

[1] Design ideas

In terms of hardware, two ESP32 chips are used, one for motor control, one for sensor and network communication, human-machine interaction, etc. At the same time, two ESP32s are used for serial communication, information transmission, and real-time status detection. The ESP32-CAM camera and WIFI module are not managed by the main control board. After power-on, the ESP32-CAM camera and WIFI module operate independently.

Separate the design of the two ESP32s, power supply, download circuit, and communication circuit, design them separately, do not interfere with each other, and minimize interference to the greatest extent.

[2] AMS1117 step-down circuit

AMS1117 is a commonly used low dropout linear regulator integrated circuit.

The project uses AMS1117-3.3, which can reduce the input voltage to 3.3V to power the main control and sensors.

[3] CH340K serial circuit

CH340K is a USB-to-serial port chip designed and produced by Nanjing Qinheng Microelectronics.

CH340K, as a USB to serial port chip, can convert the computer's USB interface into a serial communication interface, providing a convenient program download channel for ESP32. Arduino IDE can be used to download the written program code to the ESP32 chip through CH340K.

During the program development process, you can use the serial port connection established by CH340K and tools such as serial port debugging assistant to view the debugging information output by ESP32 in real time on the computer, such as program running status, variable values, error prompts, etc., which is convenient for quickly locating and solving problems in the program.

[4] Automatic download circuit

Two NPN-type transistors are usually used in the circuit to control the GPIO0 and EN pins of ESP32. The external control signal is provided by the DTR and RTS pins of the CH340K chip, which are connected to the base of the transistor through a resistor. The collector of the transistor is respectively connected to the GPIO0 and EN pins of ESP32, and the emitter is grounded.

When the computer opens the download software and operates the serial port, the download software will send a specific signal sequence to the ESP32 through CH340K to control it to enter the download mode. For example, first set the DTR pin to low level, set the RTS pin to low level, and then change it to high level. At this time, the GPIO0 pin of the ESP32 is pulled low, and the EN pin generates a rising edge. After resetting, the ESP32 detects that GPIO0 is low level and automatically enters the download start mode.

[5] PS2 controller circuit

Use the GPIO12, 13, 14, and 15 pins of the functional ESP32 to connect the PS2's controller receiver

DI/DAT: Signal flow, from the controller to the host, this signal is an 8-bit serial data, synchronously transmitted to the falling edge of the clock. The reading of the signal is completed during the process of the clock changing from high to low.

DO/CMD: Signal flow, from the host to the controller, this signal is opposite to DI, the signal is an 8-bit serial data, synchronously transmitted to the falling edge of the clock.

NC: Empty port;

GND: Power ground;

VDD: Receiver working power supply, power range 3~ 5V;

CS/SEL: Used to provide a handle trigger signal. During communication, it is at a low level.

CLK: Clock signal, issued by the host, used to maintain data synchronization.

NC: Empty port;

ACK: The response signal from the controller to the host. This signal decreases in the last cycle of each 8-bit data transmission and the CS remains low. If the CS signal does not decrease, the PS host will try another peripheral for about 60 microseconds. The ACK port was not used during programming.

[6] MPU6050 circuit

The MPU6050 integrates a 3-axis MEMS gyroscope, a 3-axis MEMS accelerometer, and an expandable digital motion processor DMP. It provides direction status for intelligent vehicle operation through IIC communication and motor ESP32 communication.

[7] Relay and motor interface

IO32 is the relay that starts the mowing motor. When IO32 is low, the relay is turned on and the mowing motor starts.

The four pins IO33, IO25, IO26, and IO27 are for PWM control of the motor drive board, which controls the forward and reverse rotation of the motor and the speed of forward and reverse rotation through different PWMs.

[8] GY-39 sensor circuit

GY-39 is a low-cost, pressure, temperature and humidity, light intensity, sensor module.

Connect GY-39 to the serial port of the functional ESP32. GY-39 uses serial communication, and the ESP32 receives the corresponding information and parses it.

[9]Screen circuit

Using 2 screens, one main and one secondary.

The main screen is a 1.8-inch TFT_LCD screen, which can display color patterns and has good display effect. It uses SPI communication and ESP32 VSPI interface.

The secondary screen is a 0.96-inch OLED screen, which can display black and white patterns and has a high definition display effect in sunlight. It can be used as an auxiliary main screen display or to display important information of smart cars, using the ESP32 IIC interface.

[10] Schematic Diagram Family Treasure

(2) PCB design

PCB is a 4-layer board with two layers of copper (GND)

Adopting a positive and negative layout, the front side has sensors, screens, interfaces, etc., and the back side has 2 ESP32s and corresponding voltage reduction chips, communication chips, etc.

The antenna part adopts a prohibited area to reduce interference in the ESP32 antenna area.

PCB component soldering adopts the method of low-temperature soldering with air gun and high-temperature soldering with electric soldering iron to reduce the cracking of components under shaking or external force.

By adopting a scientifically reasonable layout method, each electronic component is compactly and orderly placed on the PCB board, making full use of space while ensuring the shortest path of signal transmission, reducing signal interference and attenuation, and improving the overall performance of the circuit.

In the selection of components, the quality and reliability of the components were fully considered, and high-quality components from well-known brands were selected. These components have good stability and durability and can work stably for a long time in harsh working environments.

By adding necessary power filtering, signal conditioning and other circuits, as well as adopting redundant design, fault-tolerant design and other means, the stability and anti-interference ability of the PCB board are improved, and the probability of failure caused by external factors is reduced.

Program design

In terms of program design, the Modularization programming method is used to divide the entire program into multiple modules with clear functions, each module responsible for a specific task, making the code structure clear and easy to understand. When it is necessary to modify or maintain the program, relevant modules can be quickly located without getting lost in a large amount of code.

By decomposing complex systems into multiple simple modules, the complexity of each module is reduced, making it easier to design and implement. At the same time, it is also beneficial for overall analysis and optimization of the system, improving its stability and reliability.

When there is a problem with the system, Modularization design can quickly locate the module where the problem lies and conduct targeted debugging and testing.

Introduction to Programming Environment

Arduino IDE is the main programming software for Arduino and an open-source Integrated Development Environment. Based on C/C++ language, it provides developers with a simple and easy-to-use platform for writing, compiling, and uploading programs to Arduino development boards. It has cross-platform compatibility and supports mainstream operating systems such as Windows, Mac OS X, and Linux.

With a large number of open source libraries, these libraries can help developers quickly implement various functions, reducing development time and workload. At the same time, there are many sample codes available for reference, which is convenient for beginners to learn and reference.

(2) Motor ESP32 program design

The control information can be directly transmitted to the ESP32 through the handle, or the remote control information can be communicated to the motor ESP32 through the serial port through the program ESP32. At the same time, the MPU6050 posture sensor detects the motion posture in real time and corrects it.

ESP32 outputs relay signals and motor drive PWM. By controlling the PWM of two deceleration motors, it can control forward, backward, left, and right turns.

(3) Functional ESP32 programming

Mainly using the WIFI function of ESP32, using the HTTP protocol to upload data to the server, and using the MQTT protocol to receive real-time information controlled by the APP, and then the required information can be uploaded to the screen for display or debugging.

(4) Introduction to Software Design Environment

App Inventor is a visual programming language and development platform developed by Google and later maintained by the Massachusetts Institute of Technology (MIT). It uses a graphical programming interface to build application logic through simple drag-and-drop and splicing of Code Blocks, without the need to manually write a large amount of text code, greatly reducing the programming threshold.

The content of the APP first enables remote control of the ESP32, then receives data from sensors and outdoor weather data from the weather API, and obtains images from the ESP32-CAM to remotely view information from the monitoring station.

(5) Software appearance design

The main interface has remote control function, which can remotely control forward and backward, and the real-time display of the current intelligent vehicle screen is displayed below. Then you can enter the monitoring center to monitor the data of the intelligent vehicle and view real-time data.

The monitoring center has the status of servers and smart cars, offline is red, online is green.

Real-time data monitoring of intelligent vehicles displays temperature, humidity, and air pressure data uploaded by ESP32.

The outdoor weather obtained by API is supported by data provided by the China Meteorological Administration, displaying weather status and wind direction, as well as outdoor temperature and humidity. The monitoring center can also view the smart car's screen in real time.

(6) Software code design

When the button is pressed, the HTTP protocol GET request is used to access the server, and the data is uploaded to the server. Different numbers are uploaded according to the direction. When the button is released, the number 0 is uploaded, and 0 is the stop data.

Obtain image information from the server every 2 seconds. Due to the display of the HTTP protocol, it is difficult to display the animation effect.

The monitoring center uses a 1-second timer to read data once per second.

Server feedback information, if the server accesses the API successfully, the server API is green.

ESP32 upload data, if there is data upload within 10 seconds, it will show green light.

(7) Server code design

1. php

2. require("./phpMQTT.php");

3. $id=$_GET["id"];

4. if($id==""){exit("请输入id号");}

5. $server = 'mqtt.xemowo.top'; // 服务器IP

6. $port = 1883; // 服务器端口

7. $username = ''; // 用户名

8. $password = ''; // 密码

9. $client_id = 'pub_' . uniqid();

10.

11. $mqtt = new Bluerhinos\phpMQTT($server, $port, $client_id);

12.

13. if ($mqtt->connect(true, NULL, $username, $password))

14. {

15. $topic = 'esp';//主题

16.

17. if($id==0)//停车

18. {

19. $msg = "0";

20. }

21.

22. if($id==1)//前进

23. {

24. $msg = "1";

25. }

26.

27. if($id==2)//后退

28. {

29. $msg = "2";

30. }

31.

32. if($id==3)//左转

33. {

34. $msg = "3";

35. }

36.

37. if($id==4)//右转

38. {

39. $msg = "4";

40. }

41.

42. echo $id;

43.

44. $mqtt->publish($topic, $msg, 0);

45.

46. $mqtt->close();

47. }

48. else

49. {

50. echo "Time out!\n";

51. }

Gogo.php is used to send control information of the APP to MQTT through this program, and then MQTT synchronizes the data to ESP32.

Summary

Despite the significant achievements of the mobility intelligent environmental detection vehicle based on ESP32, there is still some room for improvement and broad development prospects. In terms of existing shortcomings and improvement directions, the current BMP280 sensor can only provide basic pressure and temperature data. In the future, more types of environmental sensors can be considered, such as air quality sensors (detecting a wider range of pollutant indicators such as sulfur dioxide, nitrogen oxides, ozone, etc.), soil moisture sensors (used for agricultural environmental monitoring to accurately judge soil moisture), noise sensors (monitoring environmental noise levels), etc., to expand the environmental monitoring scope of the detection vehicle and provide more comprehensive and accurate environmental information.

For the ESP32CAM camera, although the monitoring function has been realized, the image analysis ability is limited. Later, image recognition algorithms can be introduced, such as Object Detection (to identify specific plant species, animals or obstacles, such as rare plants or invasive species, in order to take protective or preventive measures in a timely manner), image classification (to judge the environmental status, such as distinguishing different landform types such as forests, grasslands, waters, etc.), etc., to improve the intelligence level of the camera, so that it can not only provide images, but also provide valuable analysis results, providing more powerful support for environmental monitoring and decision-making. The energy supply of the detection vehicle may currently have certain limitations, especially when operating continuously for a long time or driving on complex terrain.

In terms of future development prospects and application expansion, with the continuous advancement of artificial intelligence technology, inspection vehicles are expected to achieve a higher degree of intelligence and automation. For example, through Machine Learning algorithms, inspection vehicles can automatically plan detection paths based on environmental data, use reinforcement learning algorithms to autonomously learn the optimal driving strategy in different terrain and task scenarios, achieve autonomous obstacle avoidance, and even automatically execute corresponding environmental maintenance measures based on monitoring results (such as automatically adjusting the power and frequency of mowing motors to adapt to different weed growth conditions, and automatically controlling irrigation equipment based on soil moisture). By using deep learning technology, we can deeply analyze camera images and environmental data to predict environmental changes, such as early warning of natural disasters (such as fires, floods, etc.), and make comprehensive judgments based on image recognition of smoke and water level changes, combined with meteorological and terrain data, to provide more powerful support for disaster prevention.

Designed by 小恶魔OWO (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment