Completed

CompletedJLC electrothermal film - mini desktop heater

PRO JLC electrothermal film - mini desktop heater

JLC electrothermal film - mini desktop heater

License

:GPL 3.0

Description

Brand new version, if you're a brother, come and replicate it!

Heater overall size: 60 * 28 * 75. (Unit: mm)

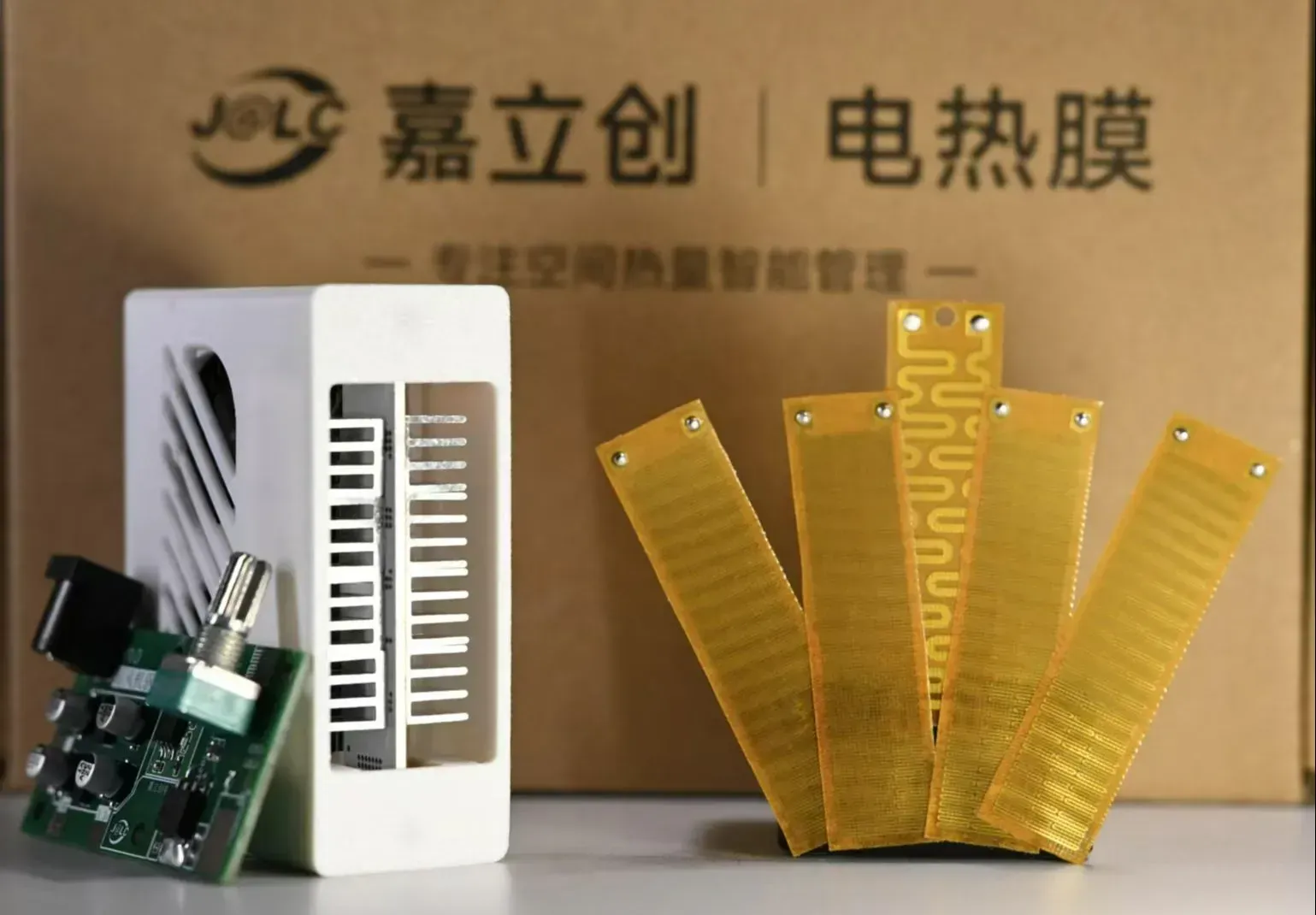

The heating element of this heater uses the PI electric heating film of Jiali Chuang electric heating film. Thanks to the high customization of JLC electric heating film, the size of the heater is more mini and portable, and the performance has also been improved. Most importantly, when ordering Jiali Chuang electric heating film, you only need to upload the corresponding heating element shape file, and the wiring is completely handed over to professional engineers. You only need to place the order, and the rest is left to Jiali Chuang electric heating film. After placing the order, you can also view the corresponding temperature curve. If there are no special requirements, you don't need to test it yourself. It's really super convenient.

Friends who want to replicate can refer to the following process information or order page remarks: M2502270021 + mini desktop heater, you can order the same heating element.

===== Appearance display =====

I won't go into detail about the circuit part, it's just a very simple NE555 variable duty cycle pulse generation circuit. The calculated frequency is just right for the hot chip, but the fan is noisy when the duty cycle is low. Then, I will show you some precautions.

===== Precautions =====

1. When making hot film samples, you must choose the type that requires adhesive backing and the type that requires welding wire. As shown in Figure 1, the diameter of the welding wire is also thoughtfully provided in the current comparison table on the JLC electric heating film ordering page, as shown in Figure 2. Please fill in the specific information according to your needs. (For example: My power supply current is 2A, and I usually choose a specification of 2A or above. It should be large rather than small, but not too large. It is enough.)

Figure 1

Figure 2

2. Not only do you need to sample the electric heater (Figure 3), but also you need to sample the aluminum-based PCB (Figure 4) and purchase the aluminum heat sink (Figure 5). For engineering, you need to place an order for both PCB boards (both sample rolls can be used). The heat sink we received is a thin piece (Figure 3) with adhesive backing. We need to paste it on the aluminum-based PCB, otherwise the PI electric heater film is flexible and difficult to fix. Finally, you need to paste the heat sink on the heat sink (Figure 6), and the position of the heat sink paste is shown in Figure 8.

Heat sink link: https://e.tb.cn/h.TzWbEsgGQk9kPez?tk=xisIeLt6fz7 (specification: 10 * 10 * 10 mm)

Figure 3

Figure 4

Figure 5

Figure 5

Figure 6 (Solder joint edge down one centimeter, paste in order)

The heating element is fixed to the M2 * 22 bolt by connecting two M2 studs and two M2 * 3 * 3.2 injection-molded copper nuts. Then it is fixed to the bracket through an injection-molded nut, as shown in Figure 7. (Installing the heating element to the bracket may be a bit difficult, so please do it twice more. The link is attached for everyone. Try to buy from the same store to save shipping costs).

Figure 7

4. As shown in Figure 8, after welding these two places, it is necessary to cut or polish them flat with pliers, otherwise the fan will be tilted.

Figure 8

5. Schematic diagram of connection (only one MOS tube needs to be welded, and the fan and hot plate are connected together)

Figure 9

6. When testing or using, be sure to pay attention to safety. Although the area is so small, the temperature of the heating element with a power of 24W is very high. Be sure to pay attention.

7. Due to the excessive heat dissipation applied to the heating film, the temperature test and the predicted temperature will be inconsistent. The trend is about 50 ℃, and it feels warm when blown on the hand.

The order documents for electric heating film and aluminum-based PCB are attached.

| Annex explains | |

| File name | Purpose |

| 3D Shell .zip | Heater housing 3D file, upload when 3D printing |

| Heating element dimension.zip | Heating film size DXF Compressed Packet, upload when ordering electric heating film |

| Installation demonstration of hot plate bracket.mp4 | Demonstration video of heating plate installation to bracket |

| Assemble Animation Demonstration.mp4 | Overall installation demonstration video |

Designed by zzron (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment