Completed

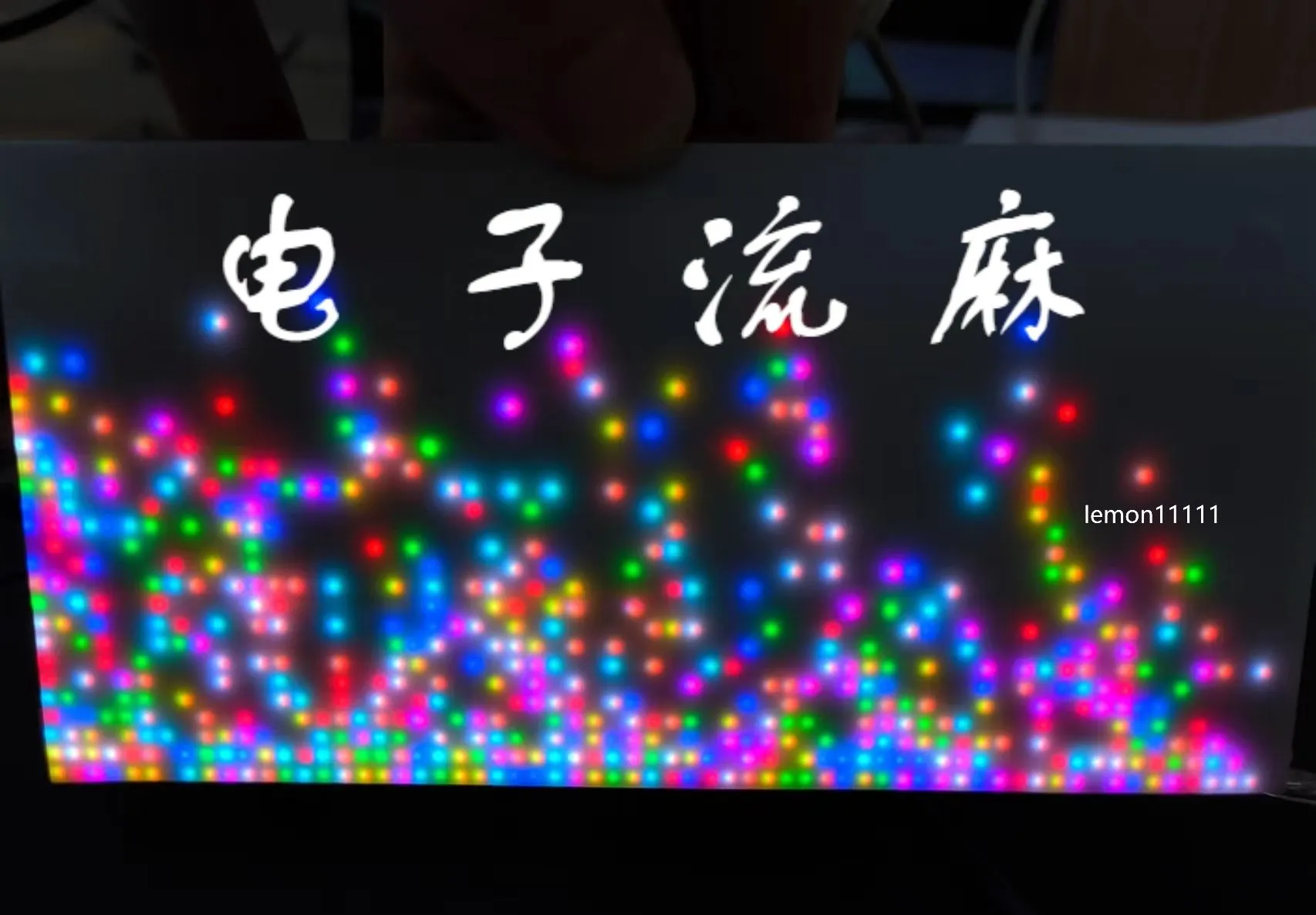

CompletedElectronic Flow Hemp

PRO Electronic Flow Hemp

Electronic Flow Hemp

276

0

0

0

Mode:Full

License

:GPL 3.0

Creation time:2024-09-29 02:17:02Update time:2024-09-29 09:57:11

Description

Designed by lemon11111 (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor.Add to Album

0

0

Share

Report

Followers0|Likes0

Related projects

Empty

Empty

Comment