Completed

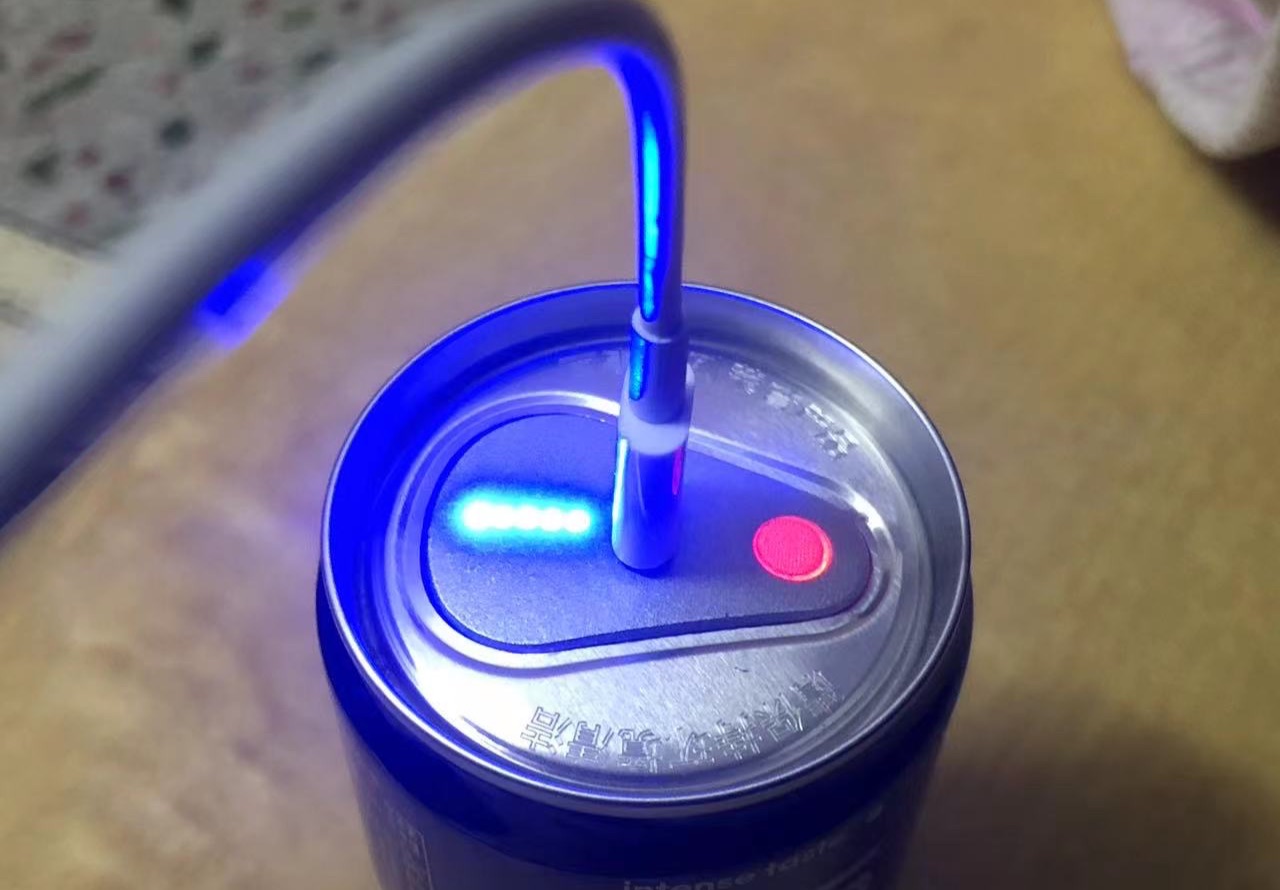

CompletedCoke Charger 4.0 (with wireless charge)

PRO Coke Charger 4.0 (with wireless charge)

Coke Charger 4.0 (with wireless charge)

311

0

0

0

Mode:Full

License

:CC BY-NC-SA 3.0

Creation time:2024-09-30 08:31:20Update time:2024-09-30 09:46:46

Description

Designed by AutoType (from OSHWHub)

a:https://oshwhub.com/big_big_a/ke-le-chong-dian-bao-dai-wu-xian

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor.Add to Album

0

0

Share

Report

Followers0|Likes0

Related projects

Empty

Empty

Comment