Completed

CompletedIO_PNP

PRO IO_PNP

IO_PNP

License

:GPL 3.0

Description

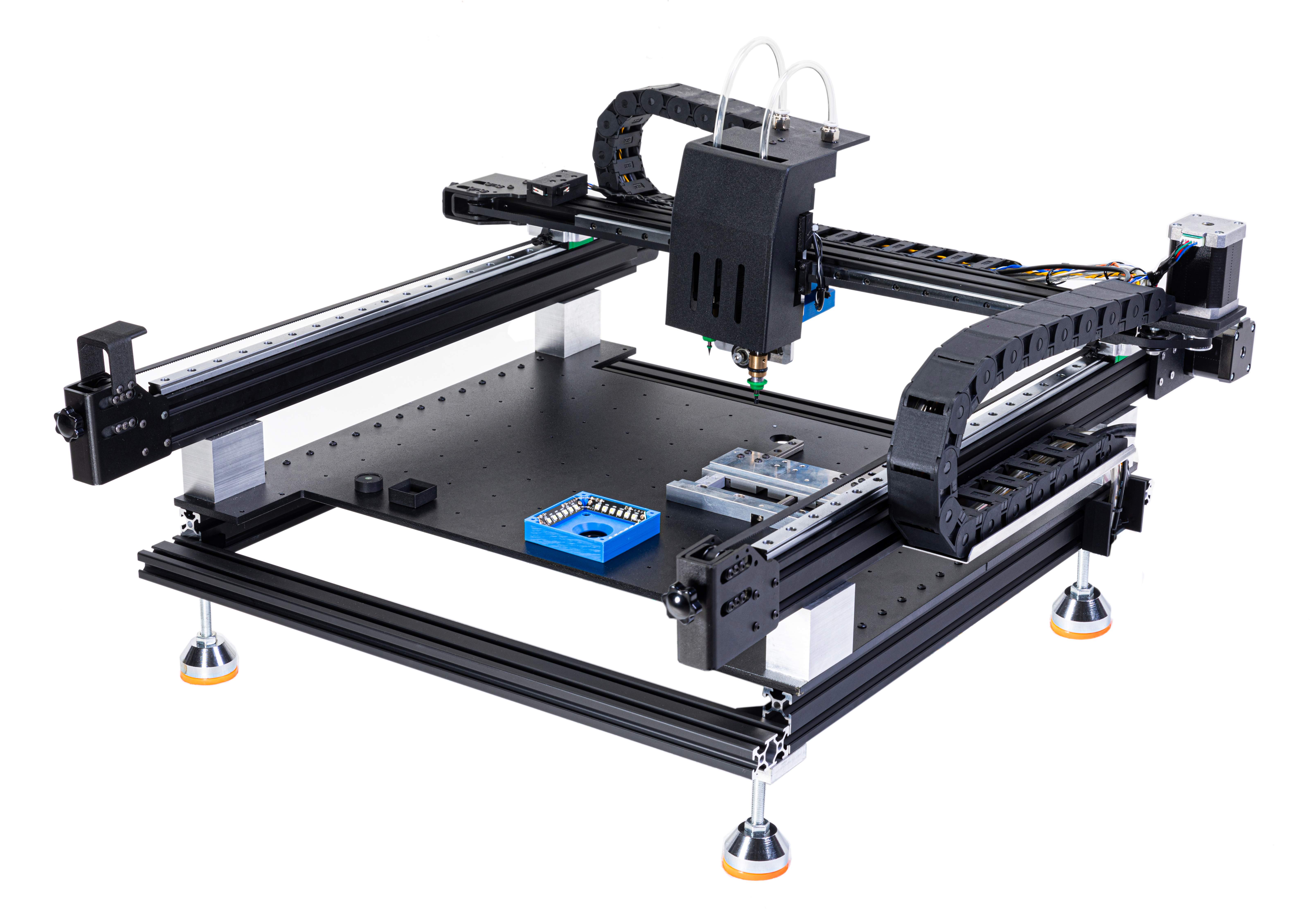

【IO】IO_PNP intelligent desktop placement machine

IO_PNP is an open source placement machine project designed by me.

The placement machine is designed to solve the problems of large placement time and high cost in the hardware development process. For this reason, the design purpose of this placement machine I designed is to make a desktop-level desktop-level machine that is exquisite, fully functional, and easy to use. Placement Assistant.

The materials for this project are open source and mainly include the following parts:

- Main body mechanical structure document of the placement machine

- Control board, feeder board, limiter, calibration board, home positioning board, LED fill light board and other hardware circuit diagrams and PCB diagrams

- Related firmware

- SMT host computer software

SMT introduction and demonstration video:

- I use 2831 components to tell you the reason to throw away the soldering iron

- [Intense] It took a month to rub the patch machine by hand. What is the effect?

- Everyone can get a patch at home - can they free their hands?

1.Project Description

For an electronics enthusiast, the most troublesome thing after PCB printing is the welding of components. This work aims to provide a desktop-level placement system for these enthusiasts to achieve the purpose of free placement.

2. Open Source Agreement

GPL 3.0

3.project-related functions

1. The machine automatically positions and completes preliminary positioning through the limit switch.

2. Visual home point recognition to complete precise positioning function

3. Complete the identification and picking of bulk feeder components through visual recognition

4. Perform position offset and angle offset correction through bottom camera recognition.

5. High-precision fully automatic feeder feeding, reducing repeated configuration problems and increasing placement speed.

4. Item Attributes

This project involves many components and consists of the following parts.

- Main part of the placement machine

There are two versions of this design, as follows:

SMT machine Ver0.1

SMT machine Ver0.2

The difference between the two versions is mainly that the main structure of the placement machine is different. The structure design of the placement machine Ver0.2 is more stable, has higher precision, and is easy to install. The base is made of iron material, which can easily use the bulk material feeder. Magnets attach to the base for easy use.

- Feida

Feida is a transliteration of the word, its English name is feeder, also known as feeder. It is a type of device that can accurately provide the required material at the designated position whenever the nozzle of the placement machine needs to pick up materials. From this perspective, Feida needs to focus on solving two problems, accuracy and stability.

The design of the feeder has also gone through a relatively long process of modification and verification. Initially, I used this 0816 feeder, which has good accuracy but poor stability.

So I focused on solving the problems of feeder accuracy and stability for a long time. Finally, I designed this feeder solution that uses PCB as the base board, dual reduction motors, and a position detector.

- Calibration board

This part is mainly used for calibration and testing of the placement machine, and its function is relatively simple.

- Main control board

This part is the main component of the placement machine control and has the following functions:

1. Drive motor movement

The main control board only reserves interfaces, and the driving motor needs to be plugged into the motor drive module. This project uses the TMC2225 motor drive module.

2. Actuator

This project has reserved 8 actuator interfaces, which are used for top camera fill light, bottom camera fill light, solenoid valve switch, pump switch, cooling fan, etc. Different actuators can be selected according to different current sizes.

3. Switch detection

Switch monitoring is mainly used to detect the signal sent from the limiter switch, which is used for the preliminary positioning function of the machine.

4. Analog signal detection

The analog signal monitoring unit is mainly used to monitor the operating temperature of the machine, the pressure of the vacuum pump, etc. to determine the relevant actions of the machine based on these signals.

5. SD card module

The control board is equipped with an SD card mainly used to save the machine's configuration information such as the maximum speed limit of the motor, etc.

6. Serial port module

The serial port module is a communication module between the control board and the host computer. Its main function is to receive signals from the host computer, complete corresponding actions, and feed back the execution results to the host computer.

7. USB module

The USB module is used with the SD card module. The main purpose is to allow the computer to recognize the SD card so that it is easier to modify the relevant configurations.

- HomeVisual Markup Board

There is a certain error in the position marked by the limiter. There is a Mark point on the Home marking board for visual positioning.

- N20 Hal Encoder

The Hall encoder is used to detect the rotation position of the motor. After a certain amount of gear rotation, the wave plate is driven to rotate, and the dial drives the material belt to advance, thereby achieving accurate material feeding.

The installation position of ordinary Hall encoders is like this.

This direction results in the direction of the motor when installed on the feeder.

This undoubtedly increases the thickness of the feeder. In order to solve this problem, I rotated the Hall sensor below 90 degrees. This is the Hall sensor I designed, which can reduce the thickness of the feeder to a great extent.

- Camera Fill Light

The placement machine is designed with a top camera and a bottom camera. Both cameras require light sources for fill light. The following is the fill light module I designed.

5.Project Progress

The basic structure has been completed and basic patch functions have been implemented.

6.Design Principles

Through modules such as guide rails, sliders, bearings, and motors, the placement machine nozzle can realize basic functions such as picking up materials and placing patches in a designated area. The camera module performs visual recognition and improves placement accuracy.

7.Software Instructions

- PC software

The project involves many modules, the core of which is the host computer that controls machine movement. The project can be seamlessly compatible with the open source openPNP framework to achieve basic functions (Figure 1). The core function is achieved through various compensations, corrections, etc. SMT machine precision placement.

Fig.1 openPNP host computer system

Fig.1 openPNP host computer system

- Control Part Firmware

The master control uses STMicroelectronics' STM32G030C8T6, and the compilation environment uses cubeIDE. The software mainly includes motor movement, protocol analysis, storage strategy, etc. The driver aspect mainly includes communication, Flash driver, motor driver, switch driver, etc.

8. Physical Display

The main structure of the placement machine has been designed in two versions, as follows:

SMT machine Ver0.1

SMT machine Ver0.2

References

https://github.com/openpnp/openpnp/wiki/Rapid-Feeder

https://makr.zone/smoothieware-new-firmware-for-pnp/500/

https://github.com/opulo-inc/lumenpnp

https://docs.mgrl.de/maschine:pickandplace:feeder:0816feeder

Other

Demonstration video: You can upload the attachment to the demonstration video. Attachments can only be long-distance transferred files of up to 50M. Files larger than 50M can be placed on other network disks or video websites. Just put the address link here.

Project attachments: Works participating in the event must upload project-related program attachments to the open source platform or personal code storage cloud. The attachment can be uploaded up to 50M (please do not upload it in the JLC workspace, there are restrictions)

Designed by qiufengluoye (from OSHWHub)

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor. Empty

Empty

Comment