Completed

CompletedFOC ballscrew linear actuator

License

:MIT License

Description

High-Precision, High-Force Linear Actuator with Advanced Servo Control

This project details the design and construction of a high-performance linear actuator leveraging the precision of a ball screw and linear rails, the rigidity of custom-machined components, and the advanced control of a Field-Oriented Control (FOC) servo system. The heart of the actuator's control is a powerful STM32G4 microcontroller, enabling sophisticated and efficient motor control for a wide range of applications demanding high accuracy and dynamic performance.

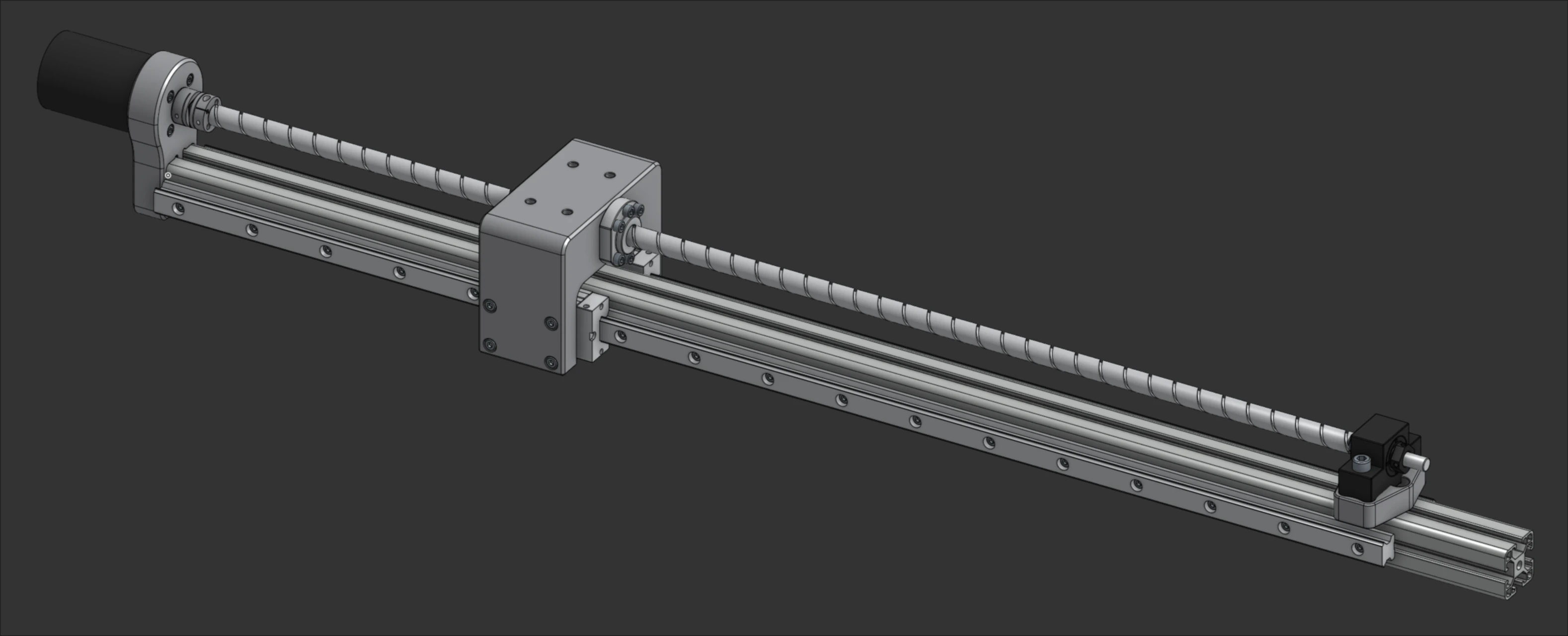

Mechanical Design: Precision and Rigidity

The mechanical assembly is engineered for accuracy, high force transmission, and long-term reliability. The core components include:

- Ball Screw: A key element for converting rotational motion into smooth, low-friction linear movement. This provides significant advantages over conventional lead screws in terms of efficiency and load-bearing capacity, making it ideal for applications requiring high thrust forces.

- Linear Rails: These provide a stable and precise guide for the moving carriage, ensuring rigidity and minimizing deflection under load. This results in highly repeatable and accurate positioning.

- Custom Machined Components: The actuator's frame and mounting points are custom-machined from aluminum to ensure a stiff and robust structure. This tailored approach allows for optimal integration of all components and enhances the overall performance of the system.

The high quality ball screw, linear rails and aluminium extrusions can be obtained from JLCMC, while the custom machined components can be ordered from JLCCNC.

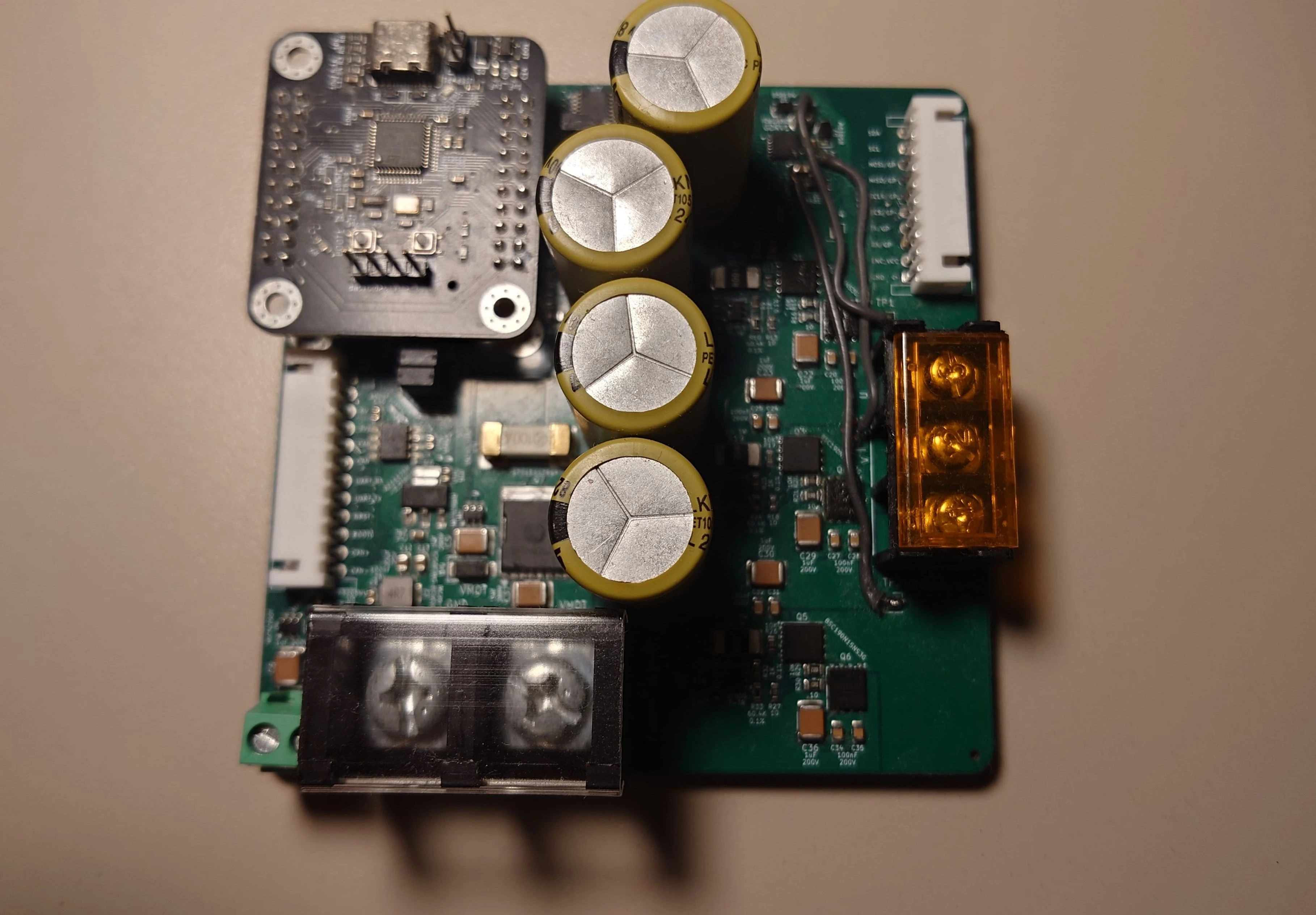

Electrical System: Advanced Motor Control

The electrical system is designed for high-efficiency and precise control of the servo motor.

- FOC Servo Motor: A brushless DC (BLDC) motor is driven by a Field-Oriented Control (FOC) algorithm. FOC provides smooth and efficient operation across a wide range of speeds and loads by precisely controlling the motor's magnetic field. This results in lower energy consumption, reduced heat generation, and improved torque control compared to simpler control methods.

- STM32G4-Based Controller: The FOC algorithm is implemented on a custom-designed controller board featuring an STM32G4 microcontroller. The STM32G4 series is specifically optimized for motor control applications, boasting a high-performance Arm Cortex-M4 core and dedicated hardware accelerators for mathematical computations crucial to FOC. This allows for real-time, high-frequency control loops necessary for demanding servo applications.

Principle of Operation: The Power of FOC

Field-Oriented Control is a sophisticated motor control technique that decouples the torque and flux-producing components of the stator current. This allows for independent and precise control of the motor's torque, similar to a separately excited DC motor. The STM32G4 microcontroller executes the complex mathematical transformations required for FOC, enabling:

- Smooth and Precise Motion: By continuously adjusting the motor's voltage and frequency, FOC ensures smooth and precise control over the actuator's position and velocity.

- High Dynamic Response: The ability to rapidly and accurately control torque allows for quick acceleration and deceleration, making the actuator suitable for dynamic applications.

- Energy Efficiency: FOC optimizes the motor's magnetic field, leading to reduced energy losses and improved overall efficiency.

Project Objectives and Applications

This project aims to deliver a linear actuator with the following key characteristics:

- High Positional Accuracy and Repeatability: Essential for tasks such as CNC machining, 3D printing, and automated assembly.

- High Force Output: Suitable for applications requiring significant pushing or pulling forces.

- Smooth and Quiet Operation: The combination of a ball screw and FOC drive ensures minimal noise and vibration.

- Dynamic and Responsive Performance: Fast and precise movements for high-throughput applications.

- High rigidity and low backlash: Guarentee of smooth movement and dynamic positional accuracy under very high loads, such as in CNC machining.

Potential applications for this high-performance linear actuator include:

- Robotics and Automation: For precise positioning of robotic arms and end-effectors.

- CNC Machinery: As a high-precision axis drive for milling machines, lathes, and laser cutters.

- 3D Printing: For accurate and repeatable movement of the print head or build plate.

- Automated Test and Measurement Equipment: For precise positioning of sensors and probes.

- Custom Automation Solutions: In any application where precise, high-force linear motion is required.

This is the linear actuator. Weighing in at over 13KG in total, it delievers extreme rigidity, high precision and repeatability, and high speed that will fulfil an extremely wide array of applications, from CNC machines all the way to Pick and Place machines. The entire assembly is attached as a STEP file.

Conclusion

By combining the mechanical advantages of a ball screw and linear rail system with the advanced control capabilities of an FOC servo drive powered by an STM32G4 microcontroller, this project will produce a versatile and high-performance linear actuator. Its precision, force, and dynamic response will make it a valuable component for a wide array of demanding automation and engineering applications.

Design Drawing

The preview image was not generated, please save it again in the editor.

The preview image was not generated, please save it again in the editor.BOM

Bom empty

Bom empty Clone

CloneProject Members

Empty

Empty

Comment