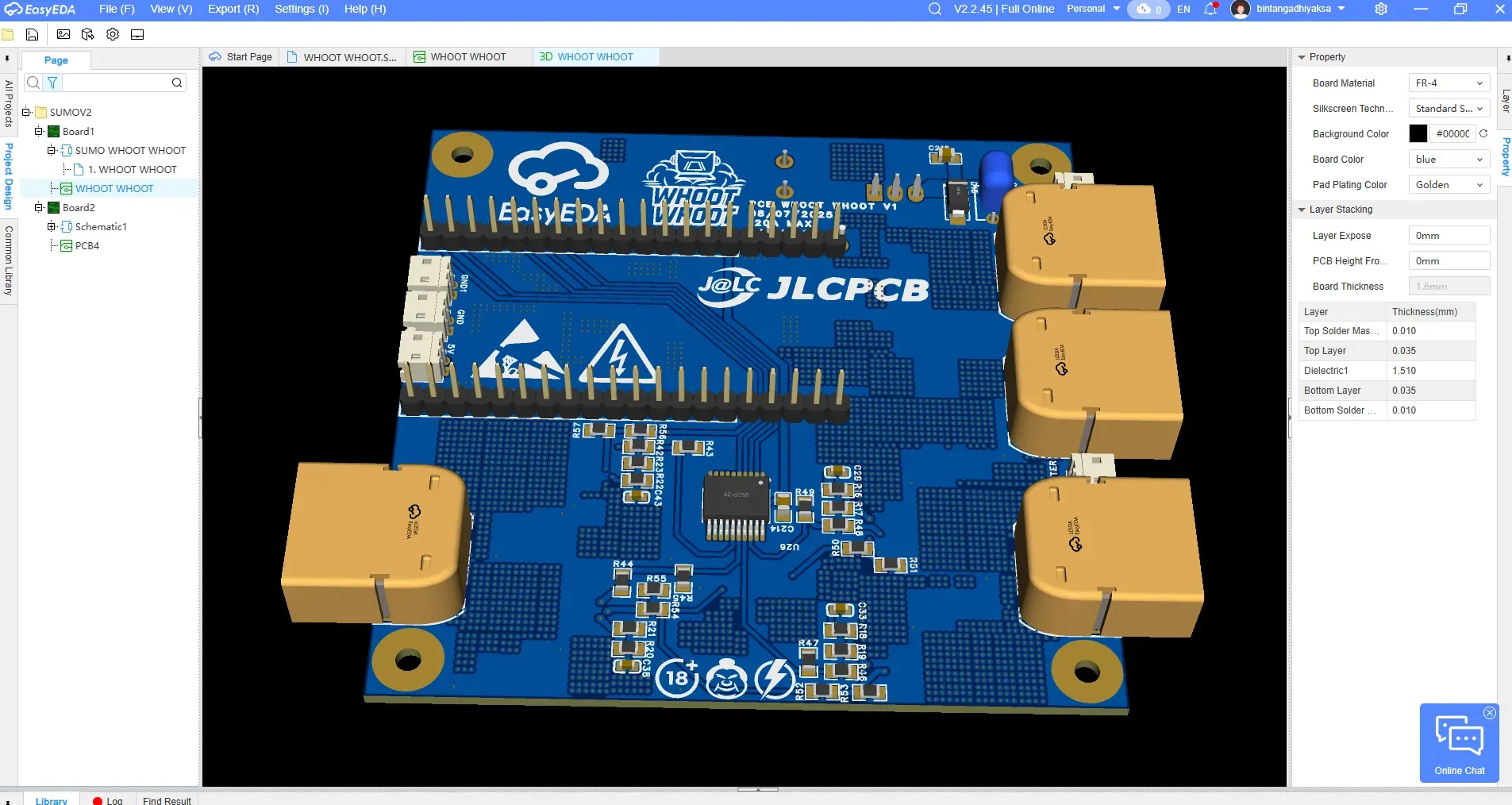

PCBMOTOR DRIVER BTN9990LV 75 AMPERE MAX, THE GREATEST MOTOR DRIVER EVERRR!!!!

2026-01-04 07:00:33

0

1

0

Dual DC Motor Driver Using BTN9990LV

Full-Bridge Bidirectional Control and Performance Optimization

1. Overview of BTN9990LV

The BTN9990LV is a high-current half-bridge motor driver IC from Infineon based on Smart Power Technology. It is designed for reliable DC motor control in automotive and industrial applications.

Key Features:

-

Type: Half-Bridge Motor Driver

-

Operating voltage: 5.5 V – 40 V

-

High output current capability (up to ±75 A peak)

-

Integrated protections:

-

Overcurrent protection

-

Overtemperature protection

-

Undervoltage lockout

-

Short-circuit protection

-

-

Supports high-frequency PWM

-

Logic-level compatible (3.3 V and 5 V microcontrollers)

2. Full-Bridge Configuration Using BTN9990LV

Since BTN9990LV is a half-bridge device, a full-bridge (H-bridge) requires two BTN9990LV ICs per motor.

IC Requirement:

-

1 bidirectional DC motor → 2 × BTN9990LV

-

2 bidirectional DC motors → 4 × BTN9990LV

This configuration allows complete control of motor direction, speed, and braking.

3. Operating Principle of Bidirectional Full-Bridge

A full-bridge enables:

-

Forward rotation

-

Reverse rotation

-

Dynamic braking

-

Free-running (coast)

Control Logic Example:

| IN_A | IN_B | Motor State |

|---|---|---|

| PWM | LOW | Forward |

| LOW | PWM | Reverse |

| HIGH | HIGH | Brake |

| LOW | LOW | Free running |

PWM signals are used for speed control, while logic levels define rotation direction.

4. Basic BTN9990LV Circuit Description

Important Pins:

-

IN – Logic/PWM input

-

EN – Enable pin

-

OUT – Motor output

-

VS – Motor supply voltage

-

GND – Ground

-

IS – Current sense output

-

SR – Slew rate control

Typical Connections:

-

VS → Motor power supply (e.g., 12 V or 24 V)

-

GND → System ground

-

IN → Microcontroller GPIO/PWM

-

EN → Logic HIGH to enable

-

OUT → Motor terminal

5. Dual Motor Control Architecture

For two motors:

-

Motor 1 → BTN9990LV (A & B)

-

Motor 2 → BTN9990LV (C & D)

Each motor has independent PWM and direction control, enabling differential drive or independent speed regulation.

6. Performance Optimization Techniques

6.1 Power Supply Design

-

Place bulk capacitors (470 µF – 1000 µF) close to the VS pin

-

Add 100 nF ceramic decoupling capacitors

-

Use short, wide PCB traces for power paths

✔ Reduces voltage drop and electrical noise

6.2 PWM Configuration

-

Recommended PWM frequency: 15 – 25 kHz

-

Above audible range

-

Improved efficiency

-

-

Always use hardware PWM for stable control

6.3 Slew Rate Control (SR Pin)

-

Use an external resistor on the SR pin

-

Slower slew rate:

-

Lower EMI

-

Reduced thermal stress

-

-

Faster slew rate:

-

Faster motor response

-

✔ Select based on application requirements

6.4 Current Sensing (IS Pin)

-

Use the IS pin to:

-

Monitor motor current

-

Detect motor stall or overload

-

Implement software-based protection

-

-

Apply ADC filtering for stable measurements

6.5 Thermal Management

-

Use large copper areas on the PCB

-

Add thermal vias under the IC

-

Attach a heatsink for continuous high-current operation (>5 A)

6.6 Additional Protection

Although BTN9990LV has internal protection:

-

Add TVS diodes on the motor supply

-

Use fuses or polyfuses

-

Implement star-grounding topology

7. Advantages of BTN9990LV Compared to Conventional Drivers

| Feature | BTN9990LV | L298 |

|---|---|---|

| Efficiency | High | Low |

| Current capability | High | Low |

| Protection | Comprehensive | Minimal |

| Voltage drop | Very low | High |

| High-frequency PWM | Yes | No |

8. Typical Applications

-

Differential drive robots

-

Automated Guided Vehicles (AGV)

-

Line follower robots

-

Industrial DC motor control

-

Smart actuators

9. Conclusion

A motor driver based on BTN9990LV is a robust and efficient solution for dual DC motor full-bridge bidirectional control. With proper power supply design, PWM configuration, and thermal management, the system achieves:

-

High efficiency

-

Stable operation

-

Reliable protection

-

Precise motor control

This makes BTN9990LV ideal for high-performance robotic and industrial motor applications.

Link:

https://drive.google.com/drive/folders/1PoshLd9N2BOwwoIAyyH2I7-uXxUVBLAV?usp=sharing

Writer:

Bintang Adhiyaksa Dani Saputro

+62822-2306-9220

bintangadhiyaksa@gmail.com

Popular Posts

More

Comment